Machine data

Document

No hay más documentos disponiblesTechnical details

| internal diameter | 250 mm |

| swing diameter | 455 mm |

| workpiece length - max. | 1200 mm |

| table rotating | -4/+8 ° |

| table speeds | 0-4000 mm/min |

| max. workpiece weight | 80 kg |

| workhead - center taper | 5 MK |

| Rotation speed of workhead | 0 - 400 1/min |

| workhead motor | 4 kw |

| 3-jaw chuck | 250 (selbstschließend) mm |

| grinding motor | 4 kW |

| coolant pump | 2,2 kW |

| Weight approx. | 2,4 t |

| machine dimensions | 3200 x 2100 mm |

Equipment | |

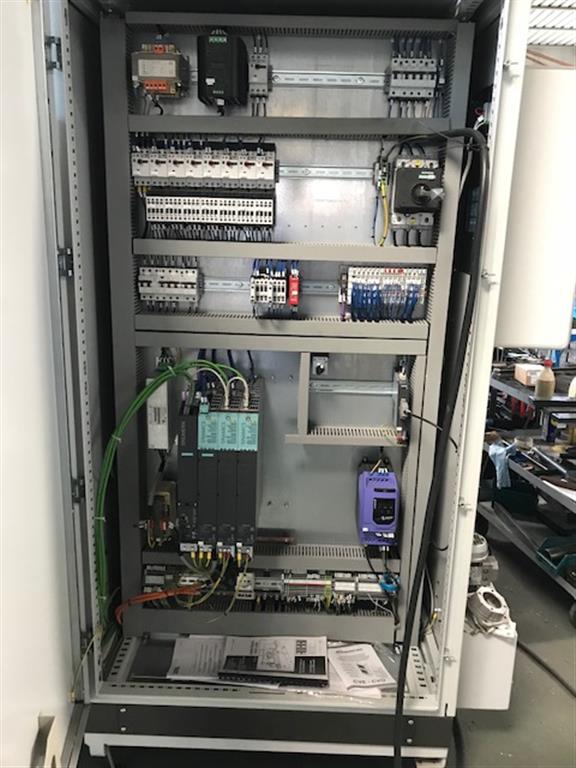

| CNC controller | Siemens 840 D oder SPS vo |

| servo motors | |

| autom. sensing device for grinding wheel | Option |

| linear scales and ballscrew | in allen Achsen |

| grinding wheel dresser | |

| fully enclosed | |

| technical documentation in German language | |

| CE-design | |

| signal lamp | |

| face grinding attachement | Durchmesser 125 mm |

| clamping chuck | 250 (selbstschließend), 1 mm |

| Magnetic and paper filter | |

| levellig elements | |

| frequency control main spindel engine | für die Innenschleifeinri |

| internal grinding spindle | RPM 28.000, diam. 60 mm. |

| internal grinding spindle | RPM 10.000, diam. 100 mm, |

| fixed steady rests | 10-100 mm, 100-170 mm |

Videos

Additional information

PERFORMANCE AND PRECISION DEGREE

Robbi grinding machines are according to the international precision normes ISO 2433.

The table movement linearity is guaranteed by a max. deviation of 0,002 mm/mt.

The obtainable grinding roundness is : 0,4m (**)

(**) for a test workpiece ground in our factory during machine testing

The CNC controls :

Wheel head movement (AXIS X)

Longitudinal table movement (AXIS Z)

Work head spindle rotation speed

The available programs permit the programming of the following grinding cycles

Plunge

Cylindrical pass

Cylindrical pass with interpolation between table and wheel movement to grind taper workpieces

Radius

The software for the workpiece grinding operation is very simple and intuitive. To facilitate the programming the software is equipped with an exemplifying graphics, to input the data for each parameter. The software, has been specially studied, so as to permit also non specialised operators to programme without any problems complex workpieces.

When the workpiece grinding programme has been completed the CNC will automatically make up a summary list, where only the geometric parameters are evidenced. This list permits with a glance to verify the complete programme; this operation is very helpful to verify eventual input data errors or to check rapidly a workpiece programme when reloaded from the file.

While the programme is in execution, it is possible to intervene and modify in real time the technologic parameters, such as: increments, dwell inversion times, sparkout passes. Also, it is possible to intervene with the jog handwheel.

The Grinding Machine is composed of :

BASE

Structure in normalised and stabilised cast iron with large ground guides. The lubrication plant supplies a constant oil flow distributed over the complete length of the guides. In the middle of the base, there is positioned the ball screw for the table longitudinal movement. On all the lower part of the perimeter are situated the recesses for machine levelling. Considering the base structure, usually a foundation is not required.

TABLE

The table is manufactured in two parts, both are in normalised and stabilised cast iron.

The lower part is composed of wide guides which are ground and accurately hand scrapped, for a better sliding. The upper part, is swivelable in the two directions, suitable for grinding tapered workpieces. It includes a micrometric device with centesimal dial gauge for taper control.

WORKHEAD

The structure in normalised, stabilised and well ribbed cast iron, allows to support the workpiece weight and the force generated by the grinding operation. The spindle rotates on high precision ball bearings, guaranteeing restricted tolerance and maximum rigidity in the working. The spindle rotation is by means of a three phase motor with variable speed controlled by an inverter.

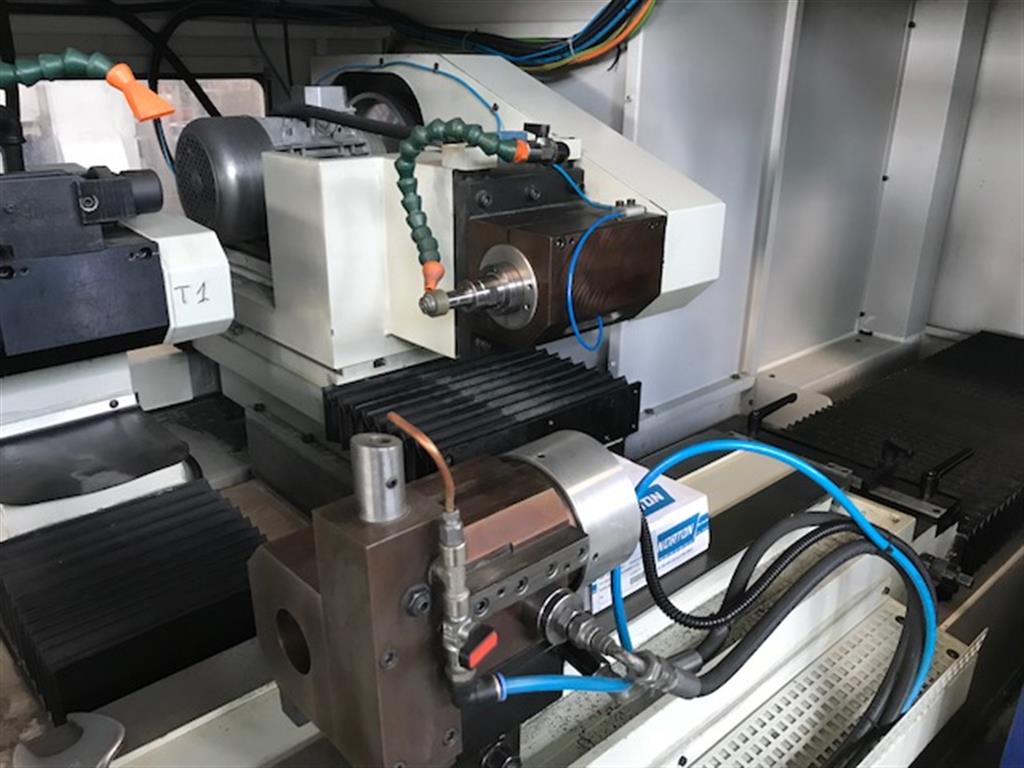

INTERNAL GRINDING SPINDLE CARRIAGE

The structure is composed of a carriage, where the internal grinding spindle is located. The working feed, is obtained by a re-circulating ball screw and preloaded nut. The screw movement is assured by a brushless motor. The incremental optic rule guarantees a wheelhead positioning precision of 0,001 mm.

INTERNAL GRINDING SPINDLE

As there are many and various types of Internal Grinding Spindles, according to the diameters and lengths that need to be ground, the machine is supplied without an internal grinding spindle, so that the customer may select which type is more suitable for his job. The machine is manufactured standard with a belt transmission suitable for diam. mm. 60, diam. mm. 80 and diam. mm. 100 internal grinding spindles. On request, high frequency spindles may be assembled.

WHEELHEAD FOR FACE GRINDING

The structure is composed of a carriage, where the face grinding device is located. The positioning is obtained by an hydraulic cylinder. The diamond dressing device is assembled on the face grinding device casing.

MANUAL FEED HANDWHEELS

Electronic type, with double selection of the increments division 0.1 - 0.01 and 0.001 mm. for wheelhead and table movements.

DIAMOND DRESSER

The internal diamond dressing device is very strong and is positioned on the table. It starts hydraulically, when the dressing operation is selected, by the operator. The dressing operation may be carried out manually or in automatic cycle.

EQUIPMENT AND ELECTRICAL PLANT

In a cooled cabinet, separate from the machine.

HYDRAULIC PLANT

The hydraulic power pack, is separate from the machine and activates the hydraulic diamond dresser and face grinding device.

LUBRICATION PLANT

The lubrication power pack, is separate from the machine and supplies continuous oil to the wheelhead guides. The recovered oil is filtered and then resent to the power pack.

The re-circulating ball screw nut for the working feed, is grease lubricated.

COOLANT PLANT

Large capacity tank for the coolant water, complete with electric equipment. Equipped with coolant magnet cleaner and coolant paper roll cleaner.

PROTECTIONS

For the protection of the operator all movable parts are covered with suitable guards. Precisely: protection casing for belts, protection casing for grinding wheel and bellows for guides. The machine is completely closed and the front protection is a sheet sliding doors with poly-carbonate shields. A safety device, does not permit the automatic cycle to start if the front sliding doors are open.

Robbi grinding machines are according to the international precision normes ISO 2433.

The table movement linearity is guaranteed by a max. deviation of 0,002 mm/mt.

The obtainable grinding roundness is : 0,4m (**)

(**) for a test workpiece ground in our factory during machine testing

The CNC controls :

Wheel head movement (AXIS X)

Longitudinal table movement (AXIS Z)

Work head spindle rotation speed

The available programs permit the programming of the following grinding cycles

Plunge

Cylindrical pass

Cylindrical pass with interpolation between table and wheel movement to grind taper workpieces

Radius

The software for the workpiece grinding operation is very simple and intuitive. To facilitate the programming the software is equipped with an exemplifying graphics, to input the data for each parameter. The software, has been specially studied, so as to permit also non specialised operators to programme without any problems complex workpieces.

When the workpiece grinding programme has been completed the CNC will automatically make up a summary list, where only the geometric parameters are evidenced. This list permits with a glance to verify the complete programme; this operation is very helpful to verify eventual input data errors or to check rapidly a workpiece programme when reloaded from the file.

While the programme is in execution, it is possible to intervene and modify in real time the technologic parameters, such as: increments, dwell inversion times, sparkout passes. Also, it is possible to intervene with the jog handwheel.

The Grinding Machine is composed of :

BASE

Structure in normalised and stabilised cast iron with large ground guides. The lubrication plant supplies a constant oil flow distributed over the complete length of the guides. In the middle of the base, there is positioned the ball screw for the table longitudinal movement. On all the lower part of the perimeter are situated the recesses for machine levelling. Considering the base structure, usually a foundation is not required.

TABLE

The table is manufactured in two parts, both are in normalised and stabilised cast iron.

The lower part is composed of wide guides which are ground and accurately hand scrapped, for a better sliding. The upper part, is swivelable in the two directions, suitable for grinding tapered workpieces. It includes a micrometric device with centesimal dial gauge for taper control.

WORKHEAD

The structure in normalised, stabilised and well ribbed cast iron, allows to support the workpiece weight and the force generated by the grinding operation. The spindle rotates on high precision ball bearings, guaranteeing restricted tolerance and maximum rigidity in the working. The spindle rotation is by means of a three phase motor with variable speed controlled by an inverter.

INTERNAL GRINDING SPINDLE CARRIAGE

The structure is composed of a carriage, where the internal grinding spindle is located. The working feed, is obtained by a re-circulating ball screw and preloaded nut. The screw movement is assured by a brushless motor. The incremental optic rule guarantees a wheelhead positioning precision of 0,001 mm.

INTERNAL GRINDING SPINDLE

As there are many and various types of Internal Grinding Spindles, according to the diameters and lengths that need to be ground, the machine is supplied without an internal grinding spindle, so that the customer may select which type is more suitable for his job. The machine is manufactured standard with a belt transmission suitable for diam. mm. 60, diam. mm. 80 and diam. mm. 100 internal grinding spindles. On request, high frequency spindles may be assembled.

WHEELHEAD FOR FACE GRINDING

The structure is composed of a carriage, where the face grinding device is located. The positioning is obtained by an hydraulic cylinder. The diamond dressing device is assembled on the face grinding device casing.

MANUAL FEED HANDWHEELS

Electronic type, with double selection of the increments division 0.1 - 0.01 and 0.001 mm. for wheelhead and table movements.

DIAMOND DRESSER

The internal diamond dressing device is very strong and is positioned on the table. It starts hydraulically, when the dressing operation is selected, by the operator. The dressing operation may be carried out manually or in automatic cycle.

EQUIPMENT AND ELECTRICAL PLANT

In a cooled cabinet, separate from the machine.

HYDRAULIC PLANT

The hydraulic power pack, is separate from the machine and activates the hydraulic diamond dresser and face grinding device.

LUBRICATION PLANT

The lubrication power pack, is separate from the machine and supplies continuous oil to the wheelhead guides. The recovered oil is filtered and then resent to the power pack.

The re-circulating ball screw nut for the working feed, is grease lubricated.

COOLANT PLANT

Large capacity tank for the coolant water, complete with electric equipment. Equipped with coolant magnet cleaner and coolant paper roll cleaner.

PROTECTIONS

For the protection of the operator all movable parts are covered with suitable guards. Precisely: protection casing for belts, protection casing for grinding wheel and bellows for guides. The machine is completely closed and the front protection is a sheet sliding doors with poly-carbonate shields. A safety device, does not permit the automatic cycle to start if the front sliding doors are open.

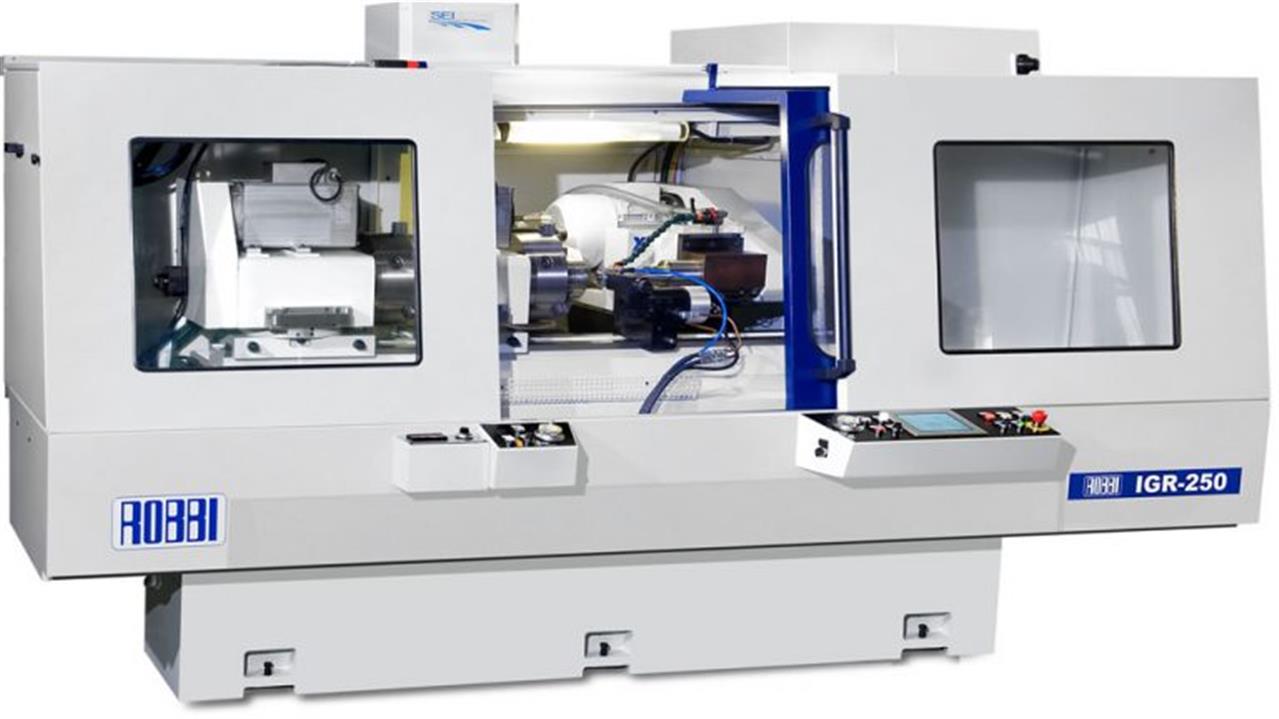

On this page you will find a an offer on a used Internal and Face Grinding Machine of type IGR 250 of the company Robbi with year of construction Fabrikneu and with stock no.: 4019-93805. The machine is manufactured by the company Kraft Werkzeugmaschinen GmbH from 64589 Stockstadt offered. The delivery time / delivery status for this machine is: ca. 4-5 months For more information, please refer to the details listed.

Documentos y videos

No hay más documentos disponibles

Machine

Internal and Face Grinding Machine