lathe-conventional-electronic

Machinelist: lathe-conventional-electronic

lathe-conventional-electronic

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-6040 · lathe-conventional-electronic

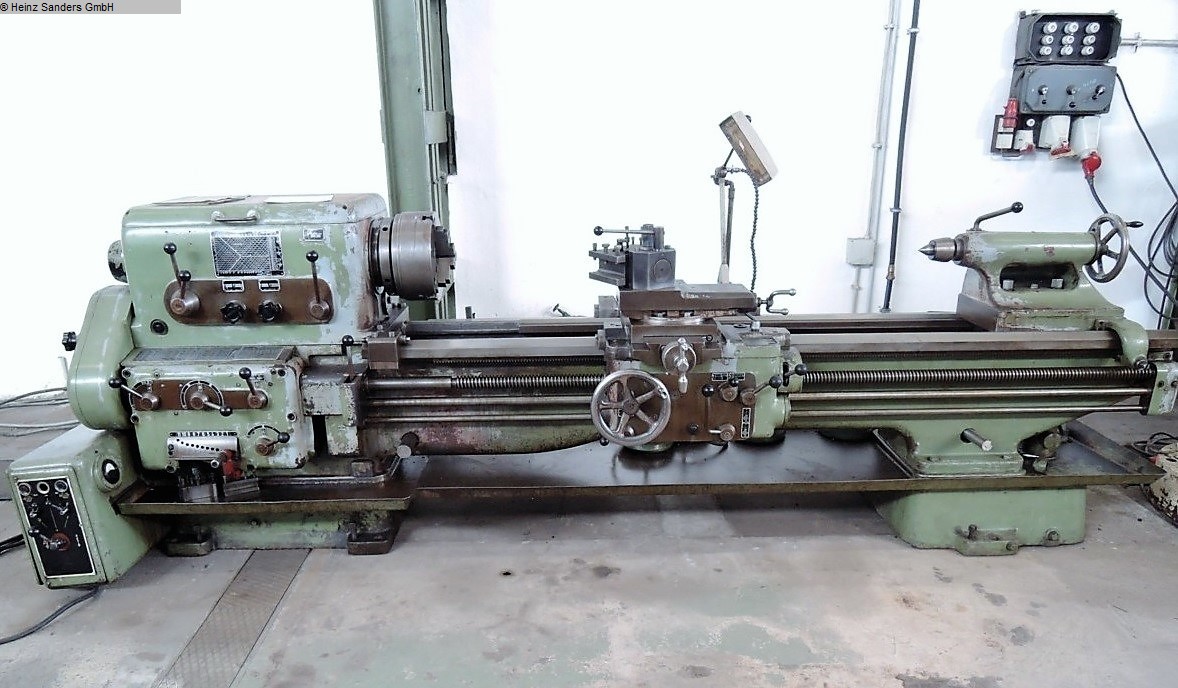

MVE BAUART VDF - V 5 - 2000 - - unbekannt -

Technical details

Electric 380Volt 3-jaw chuck Forkardt F 315 Quick change steel holder with various inserts machine light Machine feet (6 pieces) Revolving tip Coolant system

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-6622 · lathe-conventional-electronic

WEILER - Praktikant - - unbekannt -

Technical details

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-06571 · lathe-conventional-electronic

VDF-BOEHRINGER - V5 - - unbekannt -

Technical details

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200006 · lathe-conventional-electronic

ZMM - C10T - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200003 · lathe-conventional-electronic

ZMM - CU325/1000 - - NEU -

Technical details

Furnishing: - Cooling device - Machine light - chip rear wall - Spindle protection - Lathe chuck protection - Tool holder protection - Foot pedal with braking function CE - Interchangeable gears *incl. Optional equipment - 3-jaw chuck Ø 160 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type A, incl. 4 tool holders - 2-axis digital display DRO Newall

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200001 · lathe-conventional-electronic

OPTIMUM - OPTIturn TH4215D - - NEU -

Technical details

Fully equipped master and feed spindle lathes. TH 4215 with digital position indicator DPA 21 / 3462070 - Hardened and ground Z-axis guideway - Spindle mount Camlock DIN ISO 702-2 No. 6 - Precisely crafted slide - Hand wheels with adjustable fine scaling 0.04 / 0.02 mm - Quadruple steel holder - All guides can be adjusted using V-ledges - Adjustment range top slide ± 90° - Guaranteed concentricity of the spindle nose better than 0.015 mm - Main spindle running in oil bath - Smooth-running gear wheels, hardened and ground with 2 adjustable Precision tapered roller bearings - Hand wheels decoupled and tested according to EN 23125 - Two-channel right-left switch tested according to EN 23125 - Switch with life cycle calculation, tested according to EN ISO 13849 - All metric pitches in the range 0.2 to 14mm/rev and all Inch threads in the range of 72 - 2 threads per inch without changing the Change gears adjustable by shift lever in the control panel - Clockwise/counterclockwise rotation can be switched on the bed slide via the switching spindle - Central lubrication in bed slide - Meehanite cast base and machine bed in one piece - Lead screw cover - Emergency stop device with foot control - Safety handwheels with snap-out function in the X and Z axes - Tailstock for taper turning adjustable ± 10 mm - Tailstock quill and hand wheel with adjustable fine scaling 0.025 mm - Quick, easy and tool-free adjustment using a clamping lever - Heavily ribbed prism bed, induction hardened and precision ground cast iron - Coolant device with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning according to DIN - LED machine lamp in the chip guard Models TH 4210D and TH 4215D with digital readout DPA21 - User-friendly membrane keyboard, splash-proof, closed andglare-free - Glass scales scope of delivery - Fixed bezel passage Ø 15 - 145 mm - Revolving bezel passage Ø 10 - 75 mm - LED machine light - Reducing sleeve MT 6 / MT 4 - Fixed center MK 4 - Change gear set - Position stop with fine adjustment - Initial filling of the machine with quality oil - Operating tool ** Incl. special accessory OPTIMUM three-jaw lathe chuck centrically clamping Ø 250 mm ** Quick change holder SWH5-B set

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7375 · lathe-conventional-electronic

OPTIMUM - OPTIturn TH 3309D - - NEU -

Technical details

Fully equipped leading and tension spindle lathes. TH 3309D with digital position indicator DPA 21/3402040 - Hardened and ground Z-axis guideway - Spindle mount Camlock DIN ISO 702-2 No. 4 - Precisely crafted slide - Handwheels with adjustable fine scale 0.04 / 0.02 mm - Quadruple steel holder - All guides can be adjusted using V-ledges - Main spindle running in an oil bath - Gear wheels run smoothly, hardened and ground - Upper slide adjustment range ± 90 ° - Guaranteed concentricity of the spindle nose better than 0.015 mm - Handwheels decoupled and tested according to EN 23125 - Safety handwheels with push-out function in the X and Z axes - Two-channel right-left switch tested according to EN 23125 - DC 24 volt electrical system with two-channel safety circuit according to EN 23125 - Lathe chuck protection tested according to EN 23125 - Switch with life cycle calculation, tested according to EN ISO 13849 - Lockable main switch - Clockwise / counterclockwise rotation on the bed slide switchable - Lead screw cover - Tailstock for taper turning adjustable ± 10 mm - Tailstock quill and handwheel with adjustable fine scale 0.02 mm - Quick, easy and tool-free adjustment using a clamping lever - Heavily ribbed prism bed, inductively hardened and precision ground - Machine base with tool compartment on the right-hand side (left-hand side with 3 Bezels (no compartments) - Pull-out chip tray with guide rails - Emergency stop device with foot actuation - LED machine lamp integrated in the chip guard Digital position indicator DPA 21 - User-friendly membrane keyboard, splash-proof, closed and glare-free - glass rulers scope of delivery - Fixed steady rest passage Ø 6 - Ø 50 mm - Moving steady rest passage Ø 8 - Ø 30 mm - LED machine light - Reduction sleeve MK 5 / MK 3 - Two fixed centering points MK 3 - Quadruple steel holder 16 mm - Change gears set - machine base - Initial machine filling with quality oil - operating tool ** Including special accessories OPTIMUM three-jaw lathe chuck, centric clamping Ø 200 mm Camlock DIN ISO 702-2 No. 4/3442762

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200004 · lathe-conventional-electronic

ZMM - C10TM/3000 - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200002 · lathe-conventional-electronic

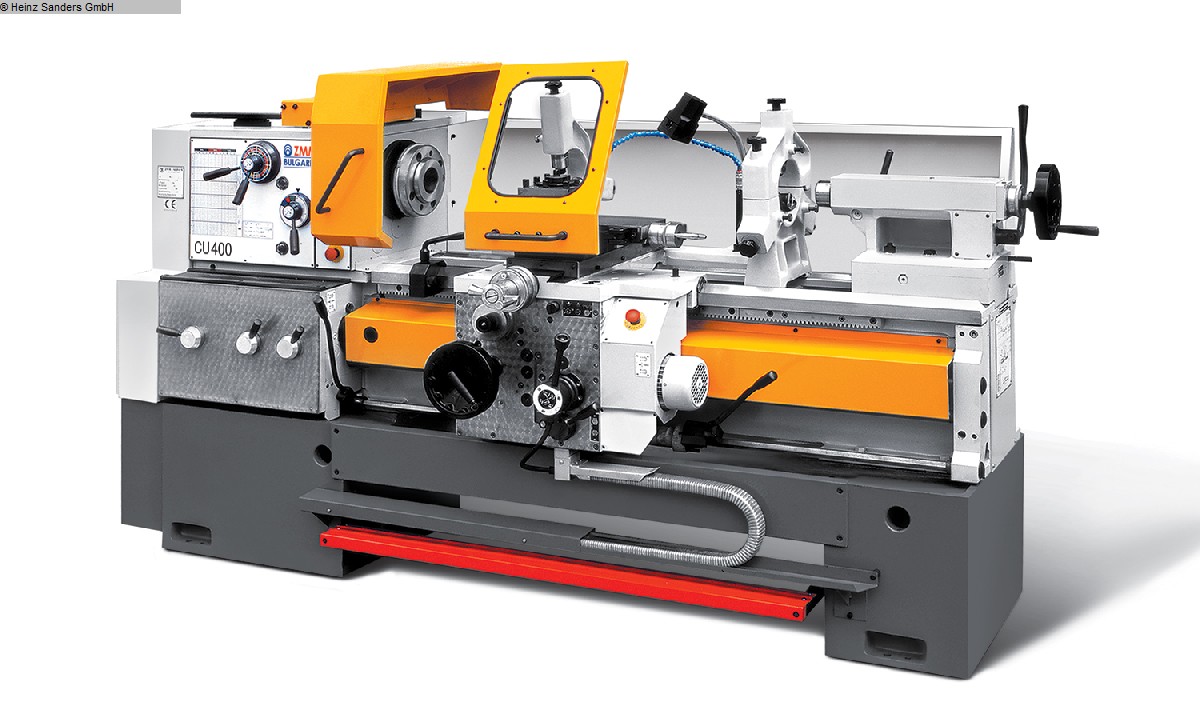

ZMM - CU400/1500 - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200005 · lathe-conventional-electronic

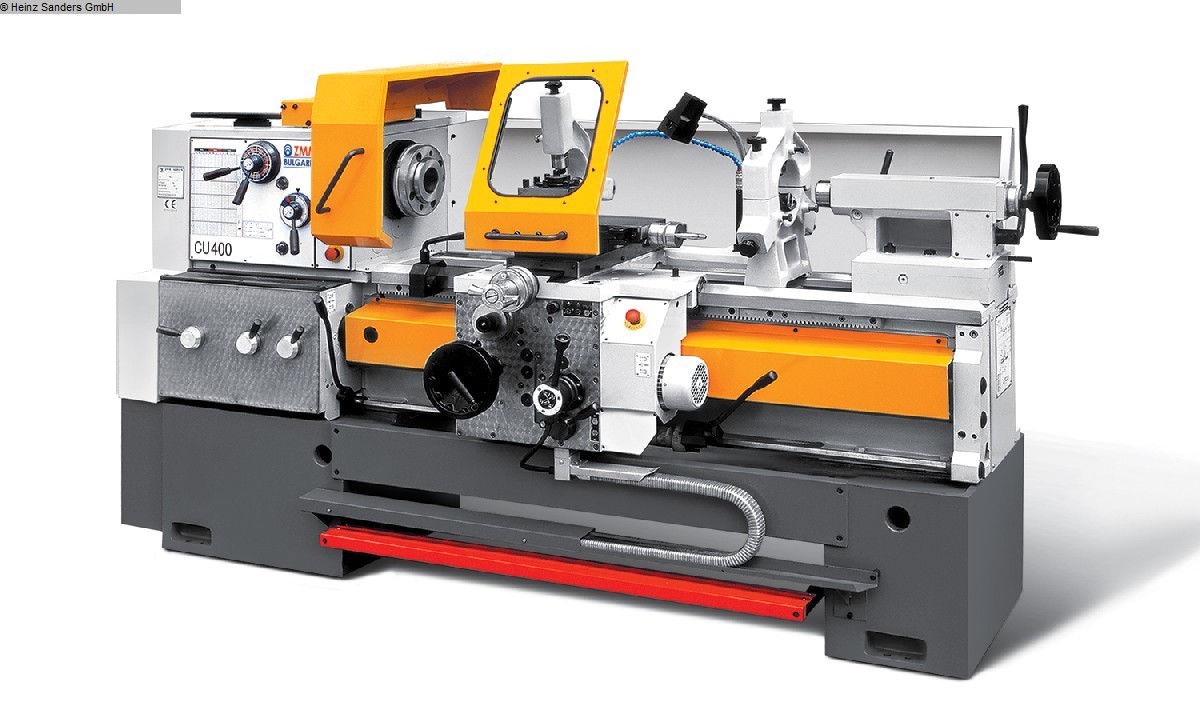

ZMM - CU400/1000 - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-06443 · lathe-conventional-electronic

GILDEMEISTER - MF 65 - - 2x 1999 / 1x 2000 - 2x 840 D

Technical details

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-D888 · lathe-conventional-electronic

HUVEMA - HU 360 x 1000 VAC - - 2022 -

Technical details

Year of make 2022 Distance between centers 1.000 mm Center height 180 mm Turning diameter above the bed 360 mm ø Turning diameter above the support 220 mm ø Turning diameter in the bag 500 mm ø Passage 38 mm ø Glasses 110 mm ø Pedestrian glasses Fixed glasses 3-Jaw Chuck 160 mm ø 4-Jaw Chuck 200 mm ø Digital readout 2 axis digital Digital readout Sino Voltage 380V Various accessories Machine size (lxwxh) 1.850 x 1.000 x 1.450 mm Machine weight 1.500 kg

- Intermach BV

- lange voor 71

- 8316BC Marknesse

- Niederlande

-

+31 (0)653235637

-

info@intermach.nl

www.intermach.nl

#2050-D273 · lathe-conventional-electronic

JMTCL - CW61125B - - 2021 -

Technical details

Brand: JMTCL Type: CW61125B Distance between centers: 1.500 mm Centerheight: 625 mm Swing over bed: 1.250 mm ø Swing over support: 850 mm ø Maximum turning diameter : 1.250ø x 1.500 mm ø Spindle boring: 135 mm ø

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207347 · lathe-conventional-electronic

BERNARDO - SMART 410-1000 V DIGITAL - - 2013 -

Technical details

** from a training workshop !! ** good condition - new price approx. 14.000 euros ** Special price on request Characteristics : - Standard with delta frequency converter - for high torque in the lower speed range . and almost constant speed under load - Infinitely variable speed control - The set speed is read via a digital display - Prism bed made of gray cast iron, induction hardened and precision ground - Central, handy switching for feeds and threads - with lead and pull spindle - Modern main spindle bearing with precision angular contact ball bearings - Standard with frequency converter and 3-axis position display - Hardened and ground gears and shafts, also in the feed gear - The speed and feed adjustment is simple - can be switched smoothly and precisely - Sliding tailstock for taper turning - Handwheel with adjustable fine scaling (0.02 mm) - The removable bridge - allows machining of large diameter workpieces Furnishing : - EASSON 3-axis digital display with LCD display - 1x 3-jaw steel chuck PO3-200 mm / D6 - 1x flat/clamping jaw chuck - 1x collet chuck including collets (inserts) - Fixed bezel - Passage diam. max. 135 mm - Revolving bezel - Passage diam. max. 65 mm - Foot pedal with braking function according to CE - MULTIFIX steel holder including insert - Protective device for steel holder - Revolver stop with fine adjustment (end stop) - electric frequency converter - Coolant device - Slip clutch - Machine light - Chip back wall - Machine swing feet - other accessories such as rotating center punch etc. - Operating instructions (DE) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207347

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207350 · lathe-conventional-electronic

BERNARDO - SMART 410-1000 V DIGITAL - - 2013 -

Technical details

** from a training workshop !! ** good condition - new price approx. 14.000 euros ** Special price on request Characteristics : - Standard with delta frequency converter - for high torque in the lower speed range . and almost constant speed under load - Infinitely variable speed control - The set speed is read via a digital display - Prism bed made of gray cast iron, induction hardened and precision ground - Central, handy switching for feeds and threads - with lead and pull spindle - Modern main spindle bearing with precision angular contact ball bearings - Standard with frequency converter and 3-axis position display - Hardened and ground gears and shafts, also in the feed gear - The speed and feed adjustment is simple - can be switched smoothly and precisely - Sliding tailstock for taper turning - Handwheel with adjustable fine scaling (0.02 mm) - The removable bridge - allows machining of large diameter workpieces Furnishing : - EASSON 3-axis digital display with LCD display - 1x 3-jaw steel chuck PO3-200 mm / D6 - 1x flat/clamping jaw chuck - Fixed bezel - Passage diam. max. 135 mm - Revolving bezel - Passage diam. max. 65 mm - Foot pedal with braking function according to CE - MULTIFIX steel holder including inserts - Protective device for steel holder - Revolver stop with fine adjustment (end stop) - electric frequency converter - Coolant device - Slip clutch - Machine light - Chip back wall - Machine swing feet - other accessories such as rotating center punch etc. - Operating instructions (DE) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207350 * Machinevideo : https://www.youtube.com/watch?v=ba6oQf-zdhs

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207349 · lathe-conventional-electronic

BERNARDO - SMART 410-1000 V DIGITAL - - 2013 -

Technical details

** from a training workshop !! ** good condition - new price approx. 14.000 euros ** Special price on request Characteristics : - Standard with delta frequency converter - for high torque in the lower speed range . and almost constant speed under load - Infinitely variable speed control - The set speed is read via a digital display - Prism bed made of gray cast iron, induction hardened and precision ground - Central, handy switching for feeds and threads - with lead and pull spindle - Modern main spindle bearing with precision angular contact ball bearings - Standard with frequency converter and 3-axis position display - Hardened and ground gears and shafts, also in the feed gear - The speed and feed adjustment is simple - can be switched smoothly and precisely - Sliding tailstock for taper turning - Handwheel with adjustable fine scaling (0.02 mm) - The removable bridge - allows machining of large diameter workpieces Furnishing : - EASSON 3-axis digital display with LCD display - 1x 3-jaw steel chuck PO3-200 mm / D6 - 1x flat/clamping jaw chuck - 1x collet chuck including collets (inserts) - Fixed bezel - Passage diam. max. 135 mm - Revolving bezel - Passage diam. max. 65 mm - Foot pedal with braking function according to CE - MULTIFIX steel holder including insert - Protective device for steel holder - Revolver stop with fine adjustment (end stop) - electric frequency converter - Coolant device - Slip clutch - Machine light - Chip back wall - Machine swing feet - other accessories such as rotating center punch etc. - Operating instructions (DE) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207349

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-D936 · lathe-conventional-electronic

ZMM - CU 500 MTRD - - 2007 -

Technical details

Brand ZMM Machine no D936 Type CU 500 MTRD Year of make 2007 Distance between centers 2000 mm Center height 250 mm Turning diameter above the bed 500 mm ø Turning diameter above the support 300 mm ø Turning diameter in the bag 700 mm ø Passage 105 mm ø Fixed glasses 3-Jaw Chuck 310 mm ø Quick-change holders 10 2 axis digital Digital readout Newall Rapid on the support Rapid traverse along and transverse movement Speed 16-1.400 RPM Engine 11 kW Voltage 380V Various accessories Machine size (lxwxh) 3.700 x 1.700 x 1.600 mm

- Siegfried Volz Werkzeugmaschinen

- Rüschebrinkstr. 151-153

- 44143 Dortmund

- Deutschland

-

+49 (0) 231 3344544

+49 (0) 231 3344533 -

info@sv-wzm.de

www.sv-wzm.de

#2073-I2358 · lathe-conventional-electronic

ZMM - CU 1250 RD - - 2006 -

Technical details

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207305 · lathe-conventional-electronic

ZMM / HUVEMA - HU 310 VAC - - 2004 -

Technical details

** New price ~ 23.000 euros ** from a training workshop (!!) Furnishing: - Spindle speed continuously adjustable in 2x switching stages - "TOS" 3-jaw lathe chuck Ø 160 mm, with spare jaws & chuck key - "NEWALL" digital display, front left - MULTIFIX steel holder with inserts - Movable tailstock - live center, incl. quick-action drill chuck - digital speed display - Change gears - Foot/spindle brake * all technical data: - Turning diameter over bed 310 mm - Distance between centers 750 mm - Spindle bore 32 mm - Turning diameter over cross slide 175 mm - bed width 200 mm - Spindle mount / DIN55027 5 - Spindle taper 4.5 M - Spindle speed infinitely variable in switching stages 2 - Spindle speed stepless 85-405; 470-2200 rpm - Number of feeds 48 - Metric thread range 0.1 - 28 mm - Thread module range 0.1 - 1.75 - Thread DP range 4 - 70 - Adjustment range cross slide 150 mm - Adjustment range top slide 95 mm - Tailstock quill diameter 40 mm - Tailstock recording 3 MK - Tailstock quill travel 100 mm - Motor power 2.2 kW - Weight 710 kg

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-D886X · lathe-conventional-electronic

ZMM - HU310 x 750 - - 2003 -

Technical details

Brand ZMM Type HU310 x 750 Year of make 2003 Distance between centers 750 mm Center height 155 mm Turning diameter above the bed 310 mm ø Turning diameter above the support 180 mm ø Passage 33 mm ø Glasses 70 mm ø Pedestrian glasses Fixed glasses 3-Jaw Chuck 3-Jaw Chuck 160 mm ø Quick-change holder Quick-change holders 4 Voltage 380V

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207330 · lathe-conventional-electronic

ZMM - SLIVEN - HU 310 - - 2002 -

Technical details

** New price ~ 20.000 euros ** from a technical college (!!) Furnishing: - Robust conventional center lathe - 3-jaw lathe chuck Ø 160 mm, with replacement jaws - "NEWALL" digital display, front left - MULTIFIX steel holder with 4x inserts - fixed bezel - moving bezel - Movable tailstock - Foot/spindle brake - Machine swing feet - User manual (PDF/NL) * all technical data: - Turning diameter over bed 310 mm - Distance between centers 750 mm - Turning diameter over support 175 mm - Spindle bore 32 mm - bed width 200 mm - Spindle mount / DIN 55027 GR 5 - Spindle taper 4.5 M - Spindle speed 85 - 2000 rpm. - Metric thread range 0.1 - 28 mm - Thread module range 0.1 - 1.75 - Thread DP range 4 - 70 - Adjustment range cross slide 150 mm - Adjustment range top slide 95 mm - Tailstock quill diameter 40 mm - Tailstock recording 3 MK - Tailstock quill travel 100 mm - Motor power 2.2 kW - Weight 770 kg * Machine link : http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207330 * Machinevideo : https://www.youtube.com/watch?v=iqU7Bkh6INo

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207346 · lathe-conventional-electronic

QUANTUM - D 460-1500 E - - 2000 -

Technical details

** Machine from a maintenance workshop ** current new price ~ 17.500 euros ** Special price on request Lathe with precision ground and induction hardened bed. Very suitable, for example, for use in workshops and teaching facilities. Furnishing: - robust lead and pull spindle lathe - RÖHM 3-jaw chuck, including replacement jaws & chuck key - foldable lathe chuck protection - MULTIFIX steel holder - size B - with 2x inserts - movable tailstock, with rotating center center - universally adjustable machine light - Chip protection back wall - EMERGENCY stop button at the front - User manual (PDF) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207346

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207331 · lathe-conventional-electronic

ZMM - SLIVEN - HU 310 - - 2000 -

Technical details

** New price ~ 20.000 euros ** from a technical college (!!) Furnishing: - Robust conventional center lathe - 3-jaw lathe chuck Ø 160 mm, with replacement jaws - "NEWALL" digital display, front left - MULTIFIX steel holder with 3x inserts - fixed bezel - moving bezel - Movable tailstock - Foot/spindle brake - Machine swing feet - User manual (PDF/NL) * all technical data: - Turning diameter over bed 310 mm - Distance between centers 750 mm - Turning diameter over support 175 mm - Spindle bore 32 mm - bed width 200 mm - Spindle mount / DIN 55027 GR 5 - Spindle taper 4.5 M - Spindle speed 85 - 2000 rpm. - Metric thread range 0.1 - 28 mm - Thread module range 0.1 - 1.75 - Thread DP range 4 - 70 - Adjustment range cross slide 150 mm - Adjustment range top slide 95 mm - Tailstock quill diameter 40 mm - Tailstock recording 3 MK - Tailstock quill travel 100 mm - Motor power 2.2 kW - Weight 770 kg * Machine link : http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207331

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-D871 · lathe-conventional-electronic

ZMM - CU 400 - - 2000 -

Technical details

Distance between centers: 1500 mm Centre height: 200 mm Swing over bed: 400 mm ø Swing over support: 220 mm ø Swing in the gap: 550 mm ø Spindle boring: 60 mm ø Steady rest: 200 mm ø 3-Jaw chuck: 250 mm ø Quick change toolholders: 3 Revolving center Digital read-out Rapid traverse on support

For centuries the lathe has been one of the most functional tools in the shaping of various materials. From clay to metal lathes have stood the test of time in terms of their reliability and practicality. In this day and age a conventional electronic lathe is an extremely versatile tool for both a home workshop and a large factory. Its ability to work on a wide range of materials and its cost-to-production ratio make it a perennial favourite.

Versatility at your fingertips with an electronic latheA conventional electronic lathe is a smart investment. Whether you're a hobbyist or an industrial professional the benefits of a conventional electronic lathe are clear. Lathes are relatively easy to operate and offer high productivity at a low cost. The advantage of a conventional electronic lathe is that it requires almost no man power and still produces high quality products. If you're in the market for a lathe or any other machining equipment check out LagerMaschinen.

LagerMaschinen: offering you convenience and cost-efficiencyIn times like these time and money are things that few can afford to waste. If you're looking to save both try shopping for used machinery online. Whether for home or business you'll find a vast array of used machinery at LagerMaschinen. Buying used machinery doesn't mean sacrificing quality because at LagerMaschinen you can find lightly used machines like a conventional electronic lathe at a price you can afford! Make the smart business choice and visit LagerMaschinen.

TOP Manufacturer:

BERNARDO - ZMM - TOS - WEILER - CAZENEUVE - WMW NILES - ZMM - SLIVEN - HUVEMA - GURUTZPE - EST-TICINO -