Machining Center - Universal

Machinelist: Machining Center - Universal

Machining Center - Universal

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100276 · Machining Center - Universal

Tongtai - CT 350 5x - - 2023 - HEIDENHAIN TNC640 (15" LCD) (5

Technical details

Factory new, immediately available CNC 5-axis universal machining center with CNC control HEIDENHAIN TNC640 (15 "LCD MONITOR) Our Taiwanese supplier is the largest manufacturer in Taiwan and also builds lathes and machining centers for well-known Japanese manufacturers. The delivery warehouse is in the Netherlands. We carry out the personnel service for these machines. Spare parts are available in the Netherlands and can be delivered at short notice. However, we are the first point of contact in all matters, whether it is delivery, assembly / commissioning, training or after-sales service. Further technical data and accessories, according to the appendix. Benefit from the favorable leasing and hire-purchase conditions of ABC Leasing. Ask us about it. Of course, you also receive from us free delivery, assembly / commissioning and ready for handover as well as control training.Also possible financing.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

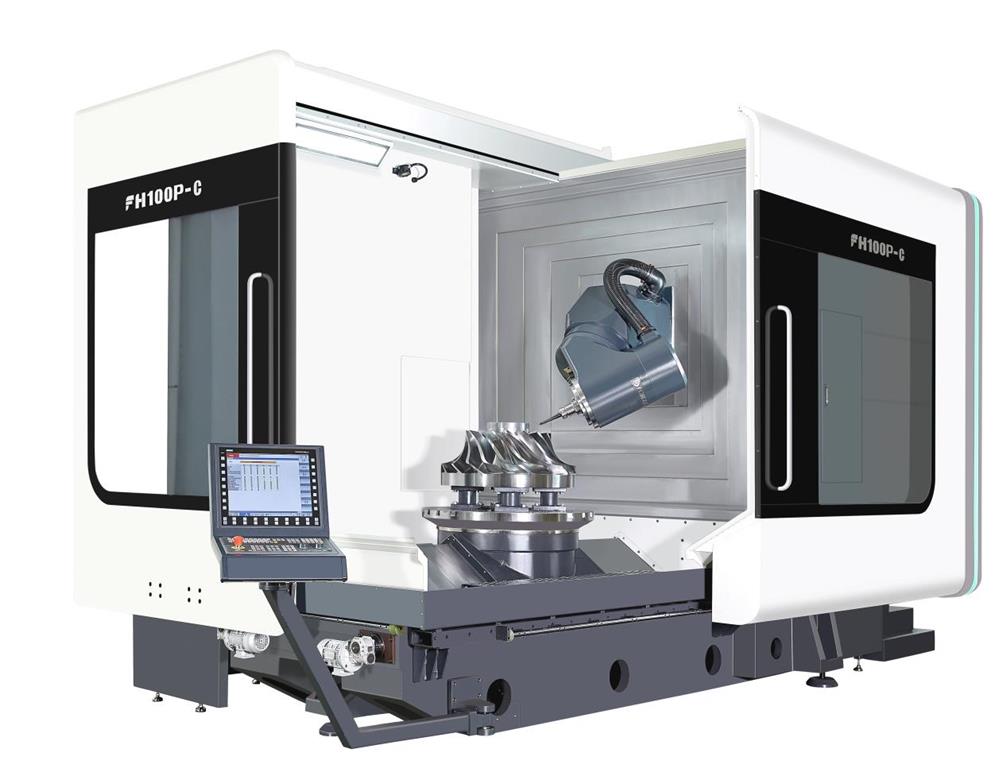

#4019-99055 · Machining Center - Universal

KRAFT - FH-60 | FH-80 | FH-100 - - 2022 - HEIDENHAIN iTNC 640 oder SIEME

Technical details

5-axis simultaneously machining center, Tandem drive NC-rotary-swivelling-table, A-axis +-120°, C-axis 360°, 3D-touch probe HEIDENHAIN TS 649, BLUM laser, 3D-quickset-software, spindle load display, MPC (machine protection control) software, signal lamp, "air clean" for cabin door, internal coolant supply 40bar, 600l incl. tempering of coolant, ring nozzle (coolant and air) chipconveyor, flush gun, MQL (minimum quantity lubrication, internal air blast, ATC-software, safety glass mode 4, DMG netservice, high accuracy package, approx. 36.500h "machine on", approx. 14.000 h "spindle on" !

- MAMACH Machinenhandel BV

- Campagneweg 10

- 4761 RM Zevenbergen

- Niederlande

-

+31 (0)168325354

-

info@mamach.nl

www.mamach.nl

#2041-V2450 · Machining Center - Universal

VICTOR - Vcenter-AX800II - - 2021 - Fanuc Series oi - MF Plus

Technical details

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03903 · Machining Center - Universal

HERMLE - C 32 U - - 2018 - ITnC 640 HEIDENHAIN

Technical details

5-axis machine with round-swivelling table, NC-swivelling table dia.650 x 540mm,A-axis from -110° - +110°, B-axis 360°, 3-D probe RENISHAW, Laser tool measuring system Ethernet interface, 18000 rpm HEIDENHAIN ITNC 640 compensation of temperature Y / Z axis, flush gun, lots of accessories, approx. 13.500 hours "spindle running", 21.000 hours "machine on"

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100287t · Machining Center - Universal

KRAFT - GT 630 5x - - 2018 - Heidenhain iTNC-530

Technical details

Factory new, immediately available CNC 5-axis universal machining center with CNC control HEIDENHAIN TNC 530 GT-630 Five axis Vertical Machining Center Type Milling Machine type Vertical Machining Center 5-Axis Travel x-as 760 mm Travel y-as 820 mm Motor 40 Kw Spindle speed 15000 rpm Tool capacity 32 Machine structure Casting components on this machine are made of high quality cast iron. The Y-axis is driven by a single ball screw at the center of gravity to ensure the parallelism of slide moving The gravity center of Y-axis moving components falls within the supporting range of sliding block, it decreases the decline of spindle and improves dynamic stability. Less overhung spindle provides excellent rigidity in heavy duty machining. Spindle unit and table The spindle is equipped with an oil lubrication bearing and oil cooling cartridge, it constrains the thermal generation and reduces the thermal expansion in the spindle. The spindle is suitable for long hour machining and available with thermal compensation mechanism (optional) The rotating axis of the table is driven by DD motor to provide higher speed an higher precision. The table is equipped with a roller gear mechanism, this provides lower friction, easy activate for high speed rotation and high precision back lash. For technical details please download the PDF brochure. Our Taiwanese supplier is the largest manufacturer in Taiwan and also builds lathes and machining centers for well-known Japanese manufacturers. The delivery warehouse is in the Netherlands. We carry out the personnel service for these machines. Spare parts are available in the Netherlands and can be delivered at short notice. However, we are the first point of contact in all matters, whether it is delivery, assembly / commissioning, training or after-sales service. Benefit from the favorable leasing and hire-purchase conditions of ABC Leasing. Ask us about it. Of course, you also receive from us free delivery, assembly / commissioning and ready for handover as well as control training. Also possible financing.

- MAMACH Machinenhandel BV

- Campagneweg 10

- 4761 RM Zevenbergen

- Niederlande

-

+31 (0)168325354

-

info@mamach.nl

www.mamach.nl

#2041-V2452 · Machining Center - Universal

OKK - VP 9000/5AX - - 2018 - Fanuc 31i-B5

Technical details

- Kirchgeorg Werkzeugmaschinen

- Frankfurter Straße 141

- 63303 Dreieich-Sprendlingen

- Deutschland

-

0049-(0)-6103-9909-0

0049-(0)-6103-9909-50 -

info@kirchgeorg.de

www.kirchgeorg.de

#1072-20446 · Machining Center - Universal

AXON LITZ - LU 620 / iTNC 640 - - 2017 -

Technical details

- Serial-No.: 6LUD00185 - Control ON: 10.918 h - Spindle ON: 2.725 h - Control: HEIDENHAIN iTNC 640 - 3-D touch probe HEIDENHAIN TS 740 - Travel distance B-Axis 50º/+110º,C-Axis 360º - Internal coolant supply through spindle 30 bar - Electr. handwheel - Laser tool measurement - chip conveyor - suction

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-981 · Machining Center - Universal

FANUC - ROBODRILL ALPHA D21LiB5 - - 2016 - FANUC 31iB5

Technical details

-BBT 30 DIRECT MOTOR -integrated electronic steering wheel -Head cooler unit. -4 - axis -Renishaw probe -extractor -no tools. *Cutting time 6.322 h

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-713 · Machining Center - Universal

FANUC ROBODRILL - ALPHA T14iFb - - 2015 - FANUC 31i-B5

Technical details

-woring hours 7851h

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-02913 · Machining Center - Universal

DMG MORI - ECOMILL 70 5 achsen - - 2015 - ITNC 620 HEIDENHAIN

Technical details

VERY NICE MACHINE CONTROL HEIDENHAIN TNC 630 CHIP CONVOYER ONLY 5 000 WORKING HOURS ISO 40 MAGASIN 32 TOOLS

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08361 · Machining Center - Universal

QUASER - MF 630C - - 2015 - Siemens 828 D

Technical details

ONLY 2800 HOURS SPINDLE WORKS Description The QUASER MF vertical machining centres are highly versatile, offering high speed, high powered machining with 4+1 and full 5-axis machining capability along with large X-axis machines with a compact footprint. Superb build quality and stability for high volume production, toolroom and subcontract machining environments. Specification Table size 500mm diameter Travels – X/Y/Z axes 800 x 700 x 610 mm A Axis + 30 deg ~ -120 deg C Axis 360 deg continous Maximum swing 630 mm Table surface to spindle nose -25mm ~ 585mm Spindle nose to tilting centre at 90 deg -25mm ~ 585mm Maximum work piece of size 630mm dia x 300mm Table load capacity 300kg Spindle taper BT40 Spindle options 10,000 / 12,000 / 15,000rpm ATC – Standard 30 Station ATC – Option 48 / 60 Station Machine weight 8750kg Features: Multi-face machining centre Siemens 828 D CNC Control 630mm maximum swing dia x 300mm high 40 Taper spindle Spindle oil chiller or ECO Chiller 30 station ATC (Options available) Coolant wash gun Coolant wash down Chip augers Cutter air blast Worklight Machine status light

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-712 · Machining Center - Universal

LITZ - LU-620 - - 2014 - iTNC 530

Technical details

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03847 · Machining Center - Universal

DECKEL MAHO DMG - DMU 50 5-Achsen - - 2013 - HEIDEN iTNC 530

Technical details

DMU 50 5 AXIS SIUMULTAN CONTROL HEIDENHAIN ITNC 530 NC round-swivelling table,2 AXIS 14000 rpm 16 positions sa 40 in magazin coolant device, cabin,+ CHIP CONVOYER

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-02836 · Machining Center - Universal

PAVENTA - SPEDD 1700 - - 2013 - HEIDENHAIN I TNC 530

Technical details

5-axis machining center 2-axis NC-°OFF TABLE internal coolant 20 BARS HP el. handwheel, Chipconveyor 80000 RPM SK 40 20 kw power TOOLS AND PAR MESURING SYSTEL HEIDENHAIN TT 140+ TS 642 nice machine

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-623 · Machining Center - Universal

MIKRON-AGIE CHARMILLES - HPM 600 U - - 2013 - HEIDENHAIN iTNC 530

Technical details

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03924 · Machining Center - Universal

MIKRON AGIE CHARMILLES - HME 500 U - 5 Axis - - 2013 - iTNC 530 Heidenhain

Technical details

5 Axis - CNC - Machining-Center Universal MIKRON AGIE CHARMILLES - HME 500 U - Swivel-Rotary-Table MAGASIN 60 TOOLS ISO 40

- MAMACH Machinenhandel BV

- Campagneweg 10

- 4761 RM Zevenbergen

- Niederlande

-

+31 (0)168325354

-

info@mamach.nl

www.mamach.nl

#2041-2780 · Machining Center - Universal

MAZAK - VTC 800/30 SR - - 2013 - Mazatrol Matrix 2

Technical details

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9168 · Machining Center - Universal

HERMLE - C 22 U - - 2013 - iTNC 530 HSCI Heidenhain

Technical details

5 Axis - CNC Machining Center Universal HERMLE - C 22 U - Good condition! - Linear axes XYZ and drives renewed - new spindle Q1/2024 - Optional: Internal coolant supply retrofitting possible (by Hermle, for an additional charge) - Additional container with paper belt filter incl. level monitoring - Conversion of coolant lubricant tank (lifting pump incl. level monitoring)

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9162 · Machining Center - Universal

DMG MORI SEIKI - DMU 50 ecoline - - 2013 - SLIMline Siemens

Technical details

CNC Machining Center Universal DMG MORI SEIKI - DMU 50 eco - 5 Axis (3+2) - swivable rotary table - new spindle at approx. 6,000 hours - WITHOUT Vices / WITHOUT Tool-Holder !

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03930 · Machining Center - Universal

DECKEL MAHO DMG - DMU 50 ECOLINE 5-Achsen 3+2 - - 2012 - HEIDENHAIN TNC 620

Technical details

CONTROL HEIDENHAIN ITNC 620 NC round-swivelling table, coolant device, cabin,

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-18014 · Machining Center - Universal

GROB - G550 - - 2012 - SIN840D sl

Technical details

5-axis machining center with SIEMENS Sinumerik 840D SL control, integrated KNOLL coolant system KF150, coolant high-pressure 80bar, coolant through the spindle, chip conveyor, pallet changer, RENISHAW OMP60 measuring probe, electromechanical tool length check, HT8 manual operating device, BLUM-Laser, GROB Spindle-diagnosis (GSD) workpiece pallets with ROEMHELD Speedy classic4 zero-point clamping system, integrated workpiece clamping, kinematics-set.

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20280 · Machining Center - Universal

LGB HURON - KX 45 Square Five2 - - 2012 - Heidenhain iTNC 530

Technical details

5-axis machining center equipped with: - CNC control Heidenhain iTNC 530 with HR 420 - movable table - Blum laser tool measurement - chip conveyor - tool changer 40-fold (HSK 63A) - IKZ 40bar - filter system 55000h Machine On, 20760h Program-Run, 23900h Spindle

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19432 · Machining Center - Universal

GROB - G 550 AB11K - - 2011 - HEIDENHAIN iTNC 530

Technical details

5-axis BAZ Equipped with: - CNC control HEIDENHAIN iTNC 530 - pallet changer 2-fold (630x630mm) - tool changer 60-fold (HSK-A63) - Swivel rotary table (A-/B-axis) - IKZ 4-38 bar - chip conveyor - belt filter system - spindle cooling 2 Machines available

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9165 · Machining Center - Universal

DECKEL MAHO - DMU 60 eVo Linear - - 2011 - iTNC 530 HSCI Heidenhain

Technical details

Machining Center Universal DECKEL MAHO - DMU 60 eVo Linear - NC-Swivel-Rotary-Table - 5 Axis - Spindle replacement 2019

When starting or expanding your industrial business machinery is of paramount importance. By buying a used machine you can stay well within your business' budget but also network with other producers in your area. LagerMaschinen's one-of-a-kind online platform lets you search for the universal machining center - or any other machine - you may need by price or location. Connect with sellers to see if their used machine is right for you then have your universal machining center delivered straight to your door. LagerMaschinen's delivery installation and connection service will hook up your universal machining center with no hassle. Start searching today for your universal machining center or other used machine on LagerMaschinen.

LagerMaschinen's used universal machining centerThe universal machining center is one of the most versatile machines available in today's market and will be a welcome addition to your new or expanding business. When shopping for a universal machining center there are many important factors to consider: number of available axes software configurations and attention to the final end product. The universal machining center is one of the most-often used machines in all of manufacturing and therefore you need to find one to most specifically suit your needs. You can find all of this information and more on LagerMaschinen's unique internet platform which will eventually lead you to a machine that perfectly suits your used machine needs. Connect with sellers search for machines in your area and have questions answered through customer service. Find your first or next universal machining center on LagerMaschinen today.

TOP Manufacturer:

DECKEL MAHO - HERMLE - DECKEL MAHO DMG - DECKEL-MAHO - DMG - DECKEL - GROB - MAHO - AXA - DMG DECKEL MAHO -