Detlef Jahn e. K. - Stockist for used machines

Machinelist:

CNC Turning- and Milling Center

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02959 · CNC Turning- and Milling Center

INDEX - IT 600 - - 2014 - Fanuc 32i-B

Technical details

CNC universal lathe INDEX IT600, year of manufacture 2014 - The following accessories would be supplied: o 2-jaw chuck Schunk ROTA 2B 200 o approx. 40 sets of clamping jaws o Approx. 45 tool holders (1x driven), but without cutting tool holder/ cutting tool o Compact handling system FMB unirobot M-10iA-12-7P o 12x 7 pallets each for various blanks Option: It would be ideal if the buyer could machine forged blanks for us in the future. We cannot define an article list in advance, but the machine utilisation would be approx. 10% of the annual capacity. Previously used for machine loading with forged blanks in the moulds Angle, cross and T-piece. Can also be used for saw cuts. However, this does not require pallets, grippers and clamping devices are available.

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02910 · CNC Turning- and Milling Center

BENZINGER - DoLittle B3 - - 2011 - Sinumerik 828 D

Technical details

Turn-mill centre for maximum precision Benzinger DoLittle B3, built in 2011 - Dolittle B3 main and counter spindle with linear tool structure Tool stations: Main spindle 10 tools + 1 stop (2 blocks 5 tools each + 1 stop) Counter spindle 11 tools (2 blocks of 5 and 6 tools) Driven tools via the swivelling axis 6 tools Machine ON/OFF: 1 shift There are 10 tool blocks in total. Technical data - Traverse path X1 axis 320mm - Traverse path Z1 axis 145mm - Traverse path Z2 axis 90mm - Traverse path Y-axis 80mm - 2x C-axis - Rapid traverse speeds X/Y/Z 30 m/min - Water-cooled motor spindle 16 mm, 15,000 1/min - BENZINGER linear tool carrier system - Swivelling NC axis with 6 driven tools Accessories: Knoll high-pressure pump Hydra cooling system Suction channel Tool holder, collets 10 tool blocks

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02927 · CNC Turning- and Milling Center

Traub - TNK 36 - - 2005 - Traub TX 8i

Technical details

CNC automatic lathe Traub TNK 36, year 2005, with bar feeder FMB turbo 5-42 This turning-milling centre is in a very good condition and equipped with 2x Y- axes and driven tools on 3 tool carriers. Tool carrier 1 = turret 12-fold driven, Y-axis +/-20mm Tool carrier 2 = front attachment 5 stations (4 driven) Tool carrier 3 = rear station 5 stations (4 driven)Y-axis +/-50mm Knoll chip conveyor (hinged belt). Cooling lubricant device with main pump for turret. and 30 bar high pressure pump for front and rear attachment. Resy cooling lubricant cleaning system flow filter approx. 25 micron. FMB bar feeder turbo 5-42 for 3m bar length, plus 15 + 25 + 36mm channels and loading bars. Accessories for TNK 36: for turret 25 fixed tool holders 10 driven tool holders for front+rear: 16 fixed tool holders 6 driven tool holders Clamping devices for HSP/GSP: 50 Hainbuch expansion chucks SK 6970 ZW/G

Turning Automatic Lathe - swiss lathe

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02926 · Turning Automatic Lathe - swiss lathe

Maier - ML 32-F2 - - 2019 - Fanuc 31i-Model B

Technical details

CNC Swiss type lathe Maier ML 32-F2, year 2019 with loading magazine FMB 3-36 Very good condition, few working hours # Vib Turn chip breaking software # FMB 3-36 is equipped with two channels 22 and 32mm. # Pick-up spindle is equipped with Forkardt chuck. Max. overlap diameter 9mm # Extended headstock stroke Z1 axis 450mm (main spindle) # Extended headstock stroke Z2-axis 340mm (pick-up spindle) # High pressure pump 140bar with paper belt filter # Pneumatic guide bush unit up to 33mm with 3 switching positions (open, closed and guiding without grippers) # Discharge of long parts # Operating hours: Control On 9781 h / In progress 6095 h # Hyfra oil cooler, model Alpha 5 New price € 443,530

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02961 · Turning Automatic Lathe - swiss lathe

Tornos - SwissDECO 36 G - - 2018 - Fanuc 31i-B5

Technical details

CNC sliding headstock lathe Tornos SwissDECO 36 G, year 2018, installation 2019, with multi-channel loading magazine Breuning-Irco, year 2019 Tornos SwissDECO 36G can work with guide bush 32mm (sliding headstock lathe) or without guide bush 36mm (short lathe). Machine ON/OFF: 22,981 h (as of 19/02/2024) Working hours: 10,575h Accessories: mult channel barloader Breuning-Irco ecoPROFI 42.6 equiped with 6 channels: 11, 16, 22, 27, 34, 40mm Knoll conveyor and filter system TISIS i4.0 software

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02949 · Turning Automatic Lathe - swiss lathe

CITIZEN - B16-E - - 2015 - Fanuc Oi-TD

Technical details

swiss type machine Citizen B16 E,built 2015 with FMB Minimag,in good conditions

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02905 · Turning Automatic Lathe - swiss lathe

TRAUB - TNL 18/9 - - 2012 - Traub System TX 8i-s

Technical details

CNC long lathe Traub TNL 18, year of construction 2011 and 2012, without loading magazine can be used as long lathe and short lathe 2 pieces immediately available, from medical technology super condition, very well equipped Machining with cutting oil WinFlex licence per machine for programming on PC workstation Sale due to type adjustment. There is a package price for the purchase of two identical machines. TNL 18, year of construction 2011: Operating hours ON/OFF 35.133h Production hours 24.384h TNL 18, year of construction 2012: Operating hours ON/OFF 30,0059h Production hours 20,498h 7+2x C-axes, main and counter spindle, 2 turrets UPPER TURRET - Positions 8 - Number of motorised positions : 8, Driven tools Speed : 12.000 [rpm] - Driven tools power : 2 [kW] - travel X/Z : 120/250 [mm] - travel Y : -40/+25 [mm] LOWER TURRET positions 8 - number of motorised positions : 8, driven tools speed : 12.000 [rpm] - driven tools Power : 2.5 [kW] - X/Z stroke : 120 / 250 [mm] - Y travel : -20 / +40 [mm]

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02950 · Turning Automatic Lathe - swiss lathe

CITIZEN - A32-VIIPL - - 2011 - Mitsubishi M70

Technical details

swiss type machine Citizen A32-VIIPL,built 2011, with Barloader FMB Turbo 3-36, Excellent conditions. Main spinle motor and spindle bearing are new. Attachmment: all comes with. It is the only one in the production.

Machining Center - Horizontal

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02914 · Machining Center - Horizontal

Mitsubishi - M-H4B - - 1998 - Fanuc 18i-M

Technical details

Machining centre - Horizontal Mitsubishi M-H4B, year of construction 1998, good ondition, regularly maintained.

Machining Center - Vertical

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02947 · Machining Center - Vertical

MORI SEIKI - NVX 5100 II/40 - - 2012 - M 750 BM Mapps 4

Technical details

Machining Center Mori Seiki NVX 5100 II/40, built 2012, with 3+2 axes 4 and 5 axles were overhauled by DMG in November 2023. Accessories: 5-axis table DDRT5AX200 Renishaw tool measurement (see picture) Inner cooling system for tooling Hinged belt conveyor with drum filter Machining hours: under power ON/OFF 32.499h working hours 8.595h

Honing Machine - External - Vertical

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

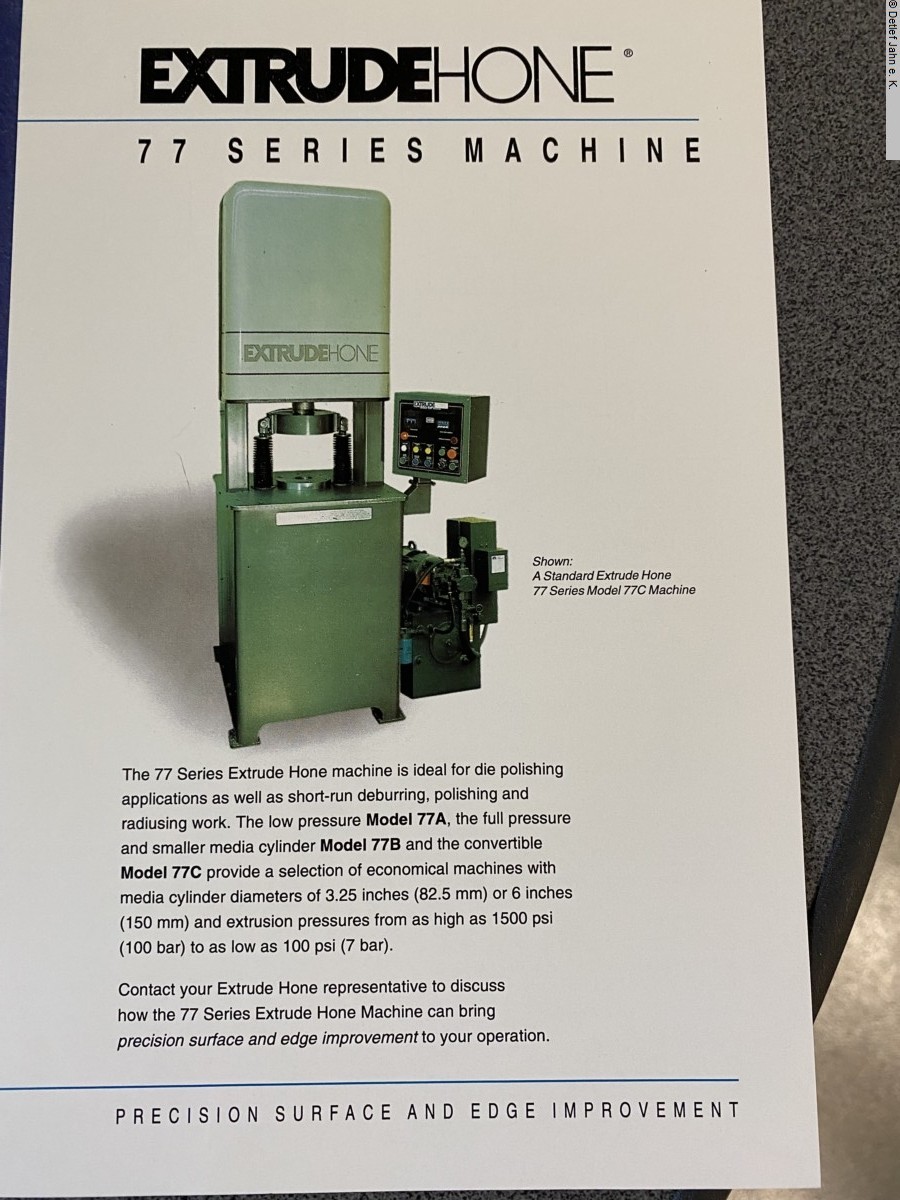

#1092-02852 · Honing Machine - External - Vertical

Kennametal - Model 77C - - 2000 -

Technical details

Kennametal Extrude Hone Machine , Model 77C, Year 2000 Abrasive Flow Machining for pressure flow lapping, or flow grinding of mech. parts. Polishing and deburring or surface modifications of complex components are carried out by means of a viscous abrasive (pressure flow lapping medium) and pressure.

Bar Stock Carrier

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02960 · Bar Stock Carrier

FMB - Turbo 3-26 - - 1998 -

Technical details

Bar feeder FMB Turbo 3-26 1 channel and bar pusher for 26mm Bar length max. 3200 mm Was attached to Gildemeister Ergomat TDA 26

Clamping Units

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

Rotary Table - Boring

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02823 · Rotary Table - Boring

SKODA - E25A - - 1989 -

Technical details

Boring mill table Skoda E25A - Boring mill table Skoda E25A - Dead weight: 8,2t - Max. Clamping weight. 25t - First commissioning: 1996 - Decommissioned and stored since 2014 - All axes are electrically controllable and ready for operation - 360° rotary drilling table ready for operation - Dimensions: see data sheet - Heidenhain rotation measuring system with digital display ready for operation - Heidenhain linear measuring system with digital display ready for operation - Boring mill table fully functional

toolholder

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-026594 · toolholder

BOLEY - d106-02 - - 2010 -

Technical details

Boley tool holder driven d106-02, gear transmission ratio 2:1, for following BOLEY machines:Boley BC 32, Boley BC 42, Boley BE 42 good conditions, suitable for cross drilling & milling,radial 4 off on stock

Perfil del comerciante: Detlef Jahn EK

Contactar con el comerciante

Parque Empresarial 8

75331 - Marca inglesa

Alemania

+ 49 (0) 7235 974820 "> + 49 (0) 7235 974820

49 0 7235

info@langdreher.de

www.langdreher.de

Perfil del comerciante

¿Estás buscando una máquina CNC perfecta? ¿Difícil?

No si tienes la pareja adecuada. Ofrecemos una experiencia inigualable y tenemos décadas de experiencia. Como operamos internacionalmente para usted, estamos seguros de encontrar la máquina adecuada para usted.

Estamos especializados en tornos automáticos, tornos CNC, máquinas multihusillo y centros de mecanizado.

Conducimos nuestras máquinas usadas con nosotros en el pasillo antes, o le mostramos esto directamente en el sitio del cliente durante la operación.

Tenemos los siguientes fabricantes para usted:

ESTRELLA; CIUDADANO; TORNOS; Maestra de niños; MANURHIN; TRAUB; ÍNDICE, MEIER; MAZAK; MORI SEIKI; OKUMA; NIIGATA; TOYOTA; HITACHI SEIKI; MITSUI SEIKI; OKK; DAEWOO; MAKINO; MATSUURA; KITAMURA; HÜLLER HILLE; El infierno EMAG; HESSAPP; BÖHRINGER; HILANDERO; EMCO; MONFORTS; NAKAMURA; TAKISAWA; BIGLIA; HECKERT; SCHARMANN; SHW; HERMLE; MIKRON; DMG; MAHO; DECKEL; STAMA; CHIRON; AXA; MATEC; HEDELIUS; SCHIESS; DÖRRIES; WALDRICH; SO; UNIÓN; TOS; Brida de honor ZAYER; FPT; ANAYAK; MIYANO; FMB; Iemca; LNS; Tsugami; etc.

Detlef Jahn eK Maschinenhandel

Parque empresarial 8, 75331 Engelsbrand / Alemania

Tel: + 49 (0) 7235 97482-0

Fax: + 49 (0) 7235 97482 24-

Mobil: + 49 (0) 173 6684254a

Correo Electrónico: info (at) langdreher.de

Gewerbepark 8

Contact Trader

Gewerbepark 8

75331 - Engelsbrand

Deutschland

+49 (0)7235 974820

+49 (0)7235 9748224

info@langdreher.de

www.langdreher.de

Contact person:

Herr Detlef Jahn +49 (0)7235 974820

Wir sind auf CNC-Drehmaschine und Bearbeitungszentren spezialisiert.

In puncto Langdreher bzw. Langdrehautomaten sind wir Ihr Ansprechpartner, wenn es um Star, Citizen, Tornos, Tsugami und andere Fabrikate geht.