WMT GmbH & Co.KG - Stockist for used machines

Machinelist:

Brush deburrer

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-67220 · Brush deburrer

BERG & SCHMID - BUE - 200 - - -Neu- -

Technical details

Datasheet

Request / Contact

Aluminium Circular Saw

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

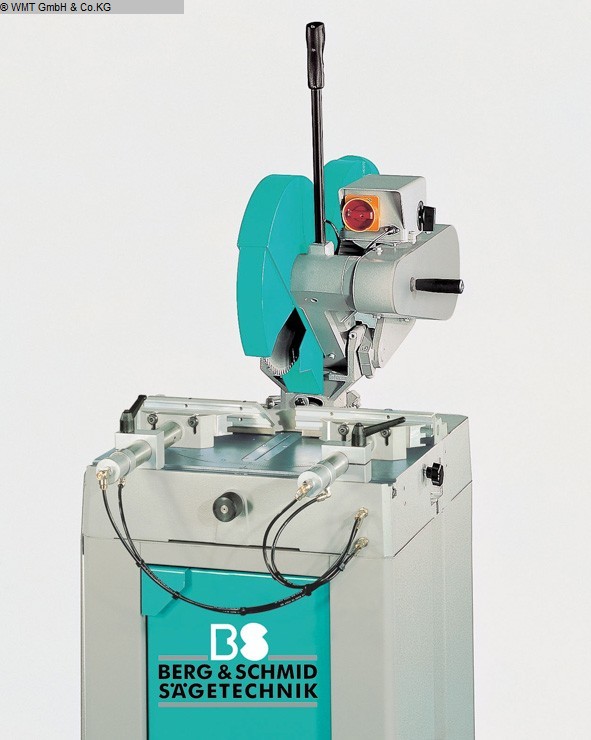

#1108-66912 · Aluminium Circular Saw

BERG & SCHMID - Alujet 351 - - -neu- -

Technical details

ATTENTION: SPECIAL PRICE - Miter left/right 45° - fixed locking points at the most important miter angles - Pneumatic double clamping device - Safety engine brake - Complete with fog spray device and machine base

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66901 · Aluminium Circular Saw

BERG & SCHMID - VELOX 350 PN - - -neu- -

Technical details

ATTENTION: SPECIAL PRICE!!! - Miter left/right 45° - head diagonal cuts up to 45° (shifter) - Pneumatic double quick clamping device Vices close when lowering - Ball bearing table - Machine base - Powerful and powerful - High-quality workmanship

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66902 · Aluminium Circular Saw

BERG & SCHMID - VELOX 350 HA MPS - - -neu- -

Technical details

- Hydropneumatic semi-automatic - Miter left/right 45° - head diagonal cuts up to 45° (shifter) - Ball bearing table - pneumatic. Double clamping device - Machine base with fog spray device - Chip extraction socket on the saw blade protective hood

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66903 · Aluminium Circular Saw

BERG & SCHMID - VELOX 350 VA MPS - - -neu- -

Technical details

Hydropneumatic fully automatic · Miter Left/Right · Bevel head cuts up to 45° (shifter) a. b. · Hydro-pneumatic control of the saw head · Pneumatic double clamping device · Pneumatic vertical clamping device · Electro-pneumatic material feed unit with material hold-down device · Vernier for length adjustment · Integrated coolant spray device · Swarf suction nozzle on the saw blade protective hood · Leftover piece length in automatic mode 210 mm MPS control: · Save cut start/end · Display of current consumption, number of pieces, cutting time... · Adjustable water cooling · Cutting pressure regulator

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66911 · Aluminium Circular Saw

BERG & SCHMID - MultiCut 530HA - - -neu- -

Technical details

Underfloor aluminum circular saw, hydropneumatic semi-automatic. · Maintenance unit for pneumatic control · Turntable with ball bearings · Suction nozzle for chip extraction system · 2 pneumatic vertical clamps · Rotation range 180° · Movable rear material stop = enlargeable cutting area · Saw blade feed continuously adjustable · Two-hand safety control Horizontal vices (option) · Mist spray device for cooling emulsion · Engine braking · Machine base · The use of our B & S Coolmatic Plus is mandatory for profile cuts necessary . Saw blade optional

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66910 · Aluminium Circular Saw

BERG & SCHMID - MultiCut 401 HA - - -neu- -

Technical details

SPECIAL PRICE!! Underfloor aluminum circular saw, hydropneumatic semi-automatic. · Maintenance unit for pneumatic control · Turntable with ball bearings · Suction nozzle for chip extraction system · 2 pneumatic vertical clamps · Rotation range 180° · Movable rear material stop = enlargeable cutting area · Saw blade feed continuously adjustable · Two-hand safety control Horizontal vices (option) · Mist spray device for cooling emulsion · Engine braking · Machine base · The use of our B & S Coolmatic Plus is mandatory for profile cuts necessary . Optional saw blade

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66904 · Aluminium Circular Saw

BERG & SCHMID - VELOX 350 VA CNC - - -neu- -

Technical details

SPECIAL PRICE!!! Hydropneumatic fully automatic · Miter Left/Right · Bevel head cuts up to 45° (shifter) a. b. · Pneumatic vertical clamping device · Vice before and after the saw blade for low-burr cuts · Material hold-down roller · Integrated coolant spray device · Swarf suction nozzle on the saw blade protective hood · Single feed 530 mm · Section length min. 4 mm max. 9,999 mm For profile cuts, the use of our B & S Coolmatic Plus is mandatory necessary. CNC Control: · With button for over 90 different sawing programs with 99 sub-programs for length, quantity and angle · Automatic feed unit 2,000 mm via ball screw Incremental feed with automatic length compensation. Adjustable for cutting lengths from 25 - 9,999 mm. · Fully hydraulic control of saw frame and clamping devices · Pre-selection of 3 different material feed speeds · Visualization of the entire workflow with simple data entry

Datasheet

Request / Contact

Band Saw - Automatic - Horizontal

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66275 · Band Saw - Automatic - Horizontal

BERG & SCHMID - SBS 550 VA-I / CNC - - -neu- -

Technical details

PROMOTIONAL PRICE!!!! 2-column high-performance automatic band saws from the SBS series The SBS series impresses with its sophisticated technology, high quality and longevity and unrivaled, sophisticated standard equipment. • Modern SNC 20 control for CNC version • Frequency-controlled saw drive • Control buttons with pictograms • Work light • Powered chip brush • Hydraulic belt tension • Clamping pressure regulation • Double vice (before and after the belt) • Creep path for positioning • Bundle tension prepared electrically and hydraulically • Chip conveyor The SNC 20 control allows you to enter up to 20 different sawing tasks (length and number of pieces) conveniently and easily. When the target dimension is entered, the control automatically calculates the saw waste and the number of feeds. Additionally, the error code display system provides quick analysis for troubleshooting.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66274 · Band Saw - Automatic - Horizontal

BERG & SCHMID - SBS 460 VA-I / CNC - - -neu- -

Technical details

PROMOTIONAL PRICE!!!! 2-column high-performance automatic band saws from the SBS series The SBS series impresses with its sophisticated technology, high quality and longevity and unrivaled, sophisticated standard equipment. • Modern SNC 20 control for CNC version • Frequency-controlled saw drive • Control buttons with pictograms • Work light • Powered chip brush • Hydraulic belt tension • Clamping pressure regulation • Double vice (before and after the belt) • Creep path for positioning • Bundle tension prepared electrically and hydraulically • Chip conveyor The SNC 20 control allows you to enter up to 20 different sawing tasks (length and number of pieces) conveniently and easily. When the target dimension is entered, the control automatically calculates the saw waste and the number of feeds. Additionally, the error code display system provides quick analysis for troubleshooting.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66260 · Band Saw - Automatic - Horizontal

BERG & SCHMID - X-Smart 3 - - -neu- -

Technical details

2-column automatic band saw X-Smart 3 • Modern CNC control, freely programmable for multiple sawing jobs various cutting lengths and quantities • Inclination of the saw frame for maximum service life of the saw band • 2-column structure linearly guided on both sides • Linear guided button for automatic cutting height detection • Hydraulic clamping pressure reduction (option) for thin-walled pipes and profiles • Hydraulic cutting pressure regulation for maximum cutting performance • Material feed carriage in bridge construction for optimal performance Transport/feed and tension of the saw material • Feed unit via precision ball screw • Double vise before and after the saw band • Electrically driven chip conveyor • Cleaning gun for easy cleaning of the system • Full fairing with easy access for maintenance and cleaning • LED work light • Minimum remaining piece length of 50 mm • Waistband tensioning device (option)

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66272 · Band Saw - Automatic - Horizontal

BERG & SCHMID - SBS 330 VA-I / CNC - - -neu- -

Technical details

PROMOTIONAL PRICE!!!! 2-column high-performance automatic band saws from the SBS series The SBS series impresses with its sophisticated technology, high quality and longevity and unrivaled, sophisticated standard equipment. • Modern SNC 20 control for CNC version • Frequency-controlled saw drive • Control buttons with pictograms • Work light • Powered chip brush • Hydraulic belt tension • Clamping pressure regulation • Double vice (before and after the belt) • Creep path for positioning • Bundle tension prepared electrically and hydraulically • Chip conveyor The SNC 20 control allows you to enter up to 20 different sawing tasks (length and number of pieces) conveniently and easily. When the target dimension is entered, the control automatically calculates the saw waste and the number of feeds. Additionally, the error code display system provides quick analysis for troubleshooting.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66271 · Band Saw - Automatic - Horizontal

BERG & SCHMID - SBS 300 VA-I / CNC - - -neu- -

Technical details

PROMOTIONAL PRICE!!!! 2-column high-performance automatic band saws from the SBS series The SBS series impresses with its sophisticated technology, high quality and longevity and unrivaled, sophisticated standard equipment. • Modern SNC 20 control for CNC version • Frequency-controlled saw drive • Control buttons with pictograms • Work light • Powered chip brush • Hydraulic belt tension • Clamping pressure regulation • Double vice (before and after the belt) • Creep path for positioning • Bundle tension prepared electrically and hydraulically • Chip conveyor The SNC 20 control allows you to enter up to 20 different sawing tasks (length and number of pieces) conveniently and easily. When the target dimension is entered, the control automatically calculates the saw waste and the number of feeds. Additionally, the error code display system provides quick analysis for troubleshooting.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66223 · Band Saw - Automatic - Horizontal

BERG & SCHMID - GBS 305 VA-I CNC - - - neu - -

Technical details

Demonstration system for a SPECIAL PRICE!! Fully automatic miter band saw • miter left 45° automatic operation • miter left 60° semi-automatic operation (cuts without programming) • Material height sensor (automatic cut start recognition) • Frame and gear made from one piece, very quiet cut and very low vibration • Removable chip tray (disinfection) • Shockproof and ergonomic control panel with oil-resistant EPDM cover • Top access to the saw, material and feed unit • Hinged safety cover • Fine feed adjustment • Semi-auto. Cut! • Optimize work processes with CNC control Possibility to enter various parameters such as quantities and material lengths, automatic calculation of the cutting channel • CNC control for 10 different saw programs with 99 sub-programs for different lengths and quantities, e.g. 1 cutting program with various section lengths • Automatic feed unit (CNC) via ball roller spindle incremental feed with automatic length compensation. Adjustable for section lengths of 2 mm to 9,999 mm, remainder length 170 mm. Inclusive: - Micro-spray device - Leveling elements

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66217 · Band Saw - Automatic - Horizontal

BERG & SCHMID - GBS 255 Super VA-I MPS - - - neu - -

Technical details

Miter band saw, fully automatic GBS 250 Super VA-I MPS • Miter left. 45° automatic operation • Miter left. 60° semi-automatic operation (cuts without programming) • Shockproof and ergonomic control panel with oil-proof EPDM cover a. • Material height sensor c. (Automatic cut start detection) • Frame and gearbox made from one piece, very quiet cutting and very low vibration • Chip tray can be removed (disinfection) • Easy access to the saw, material and feed unit • Foldable safety cover • Fine feed adjustment • Semi-automatic. Cut! Saw automatically with microprocessor control Adjustable for 2 program levels Semi-automatic operation Fully automatic operation Start after entering the desired number and length: material cut- Cutting execution and piece counting until the program is fulfilled • MPS control for entering the desired number of feeds • All important machine data is shown on the LED display during the Cutting process displayed (power consumption, cutting time, number of pieces) • The entered data is in RAM memory • The autodiagnostic circuit automatically shows all irregularities as an error message and checks the entire process • Feed unit mounted floating. • Length adjustment via handwheel and vernier with mechanical position indicator. Adjustable for section lengths from 2.5 mm to 420 mm or through Automatic reversing can be repeated 1 - 29 times, remaining piece length 210 mm

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66226 · Band Saw - Automatic - Horizontal

BERG & SCHMID - GBS 310/400 VA-I CNC - - - neu - -

Technical details

Miter band saw, fully automatic, GBS 310/400 VA-I CNC • miter left 45° automatic operation • miter left 60° semi-automatic operation (cuts without programming) • Material height sensor (automatic cut start detection) • Frame and gear made from one piece, very quiet cut and very low vibration • Removable chip tray (disinfection) • Shockproof and ergonomic control panel with oil-resistant EPDM cover • Top access to the saw, material and feed unit • Hinged safety cover • Fine feed adjustment • Semi-auto. Cut! • Optimize work processes with CNC control Possibility to enter various parameters such as quantities and material lengths, automatic calculation of the cutting channel • CNC control for 10 different saw programs with 99 sub-programs for different lengths and quantities, e.g. 1 cutting program with various section lengths • Automatic feed unit (CNC) via ball roller spindle incremental feed with automatic length compensation. Adjustable for section lengths of 2 mm to 9,999 mm, remainder length 170 mm.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66252 · Band Saw - Automatic - Horizontal

BERG & SCHMID - K-tech DG 1.202 - - - neu - -

Technical details

2-column double miter band saw for quick cutting with pusher system P15. Option P30 Hydraulic saw frame lowering • NC controlled • Automatic angular positioning from + 60° to – 60° High quality automatic miter adjustment Special development for cutting profiles and beams. The highest positioning accuracy is achieved via the new “B&S positioning system”. reached. An intelligent NC control ensures smooth interaction of linear encoder and self-braking positioning motor in conjunction with a reliable hydraulic brake using large radial center positioning. The work table is supported by high-quality preloaded bearings, which ensure very smooth rotation. CNC Control A CNC control allows the programming of up to 90 cutting programs with different section lengths, quantities and mitres. Positioning system gripping on both sides The B&S pusher system, feeding and positioning system, is marked “on both sides “Opening gripping tongs” which are hydraulically controlled. This ensures safe gripping and transport of materials and Bundles that deviate slightly from the ideal shape. The pusher system is separate constructed and ground using ball-bearing linear guides Rack and guided by a frequency-driven, robust geared motor.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66251 · Band Saw - Automatic - Horizontal

BERG & SCHMID - K-tech DG 802 - - - neu - -

Technical details

2-column double miter band saw for quick cutting with pusher system P15. Option P30 Hydraulic saw frame lowering • NC controlled • Automatic angular positioning from + 60° to – 60° High quality automatic miter adjustment Special development for cutting profiles and beams. The highest positioning accuracy is achieved via the new “B&S positioning system”. reached. An intelligent NC control ensures smooth interaction of linear encoder and self-braking positioning motor in conjunction with a reliable hydraulic brake using large radial center positioning. The work table is supported by high-quality preloaded bearings, which ensure very smooth rotation. CNC Control A CNC control allows the programming of up to 90 cutting programs with different section lengths, quantities and mitres. Positioning system gripping on both sides The B&S pusher system, feeding and positioning system, is marked “on both sides “Opening gripping tongs” which are hydraulically controlled. This ensures safe gripping and transport of materials and Bundles that deviate slightly from the ideal shape. The pusher system is separate constructed and ground using ball-bearing linear guides Rack and guided by a frequency-driven, robust geared motor.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66218 · Band Saw - Automatic - Horizontal

BERG & SCHMID - GBS 255 VA-I CNC - - - neu - - CNC

Technical details

Miter band saw, fully automatic GBS 255 Super VA-I CNC • miter left 45° automatic operation • miter left 60° semi-automatic operation (cuts without programming) • Material height sensor (automatic cut start detection) • Frame and gearbox made from one piece, very quiet cut and very low vibration • Removable chip tray (disinfection) • Shockproof and ergonomic control panel with oil-resistant EPDM cover • High performance positioning with incremental encoder (CNC) c. • Top access to the saw, material and feed unit • Hinged safety cover • Fine feed adjustment • Semi-auto. Cut! • Optimize work processes with CNC control Possibility to enter various parameters such as quantities and material lengths, automatic calculation of the cutting channel • CNC control for 10 different saw programs with 99 sub-programs for different lengths and quantities, e.g. 1 cutting program with various section lengths • Automatic feed unit (CNC) via ball roller spindle incremental feed with automatic length compensation. Adjustable for section lengths of 2 mm to 9,999 mm, remainder length 170 mm.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66245 · Band Saw - Automatic - Horizontal

BERG & SCHMID - K-tech 1200 H - - - neu - -

Technical details

2-column band saw for quick cutting, K-tech 1200H with pusher system P 30. P 60 (option), Fast, quiet and ergonomic cutting Special development for cutting profiles and beams as well as solid material. The material is fixed vertically on and section sides. The machine is from K-tech 800 H standard with an additional horizontal vice equipped. The interaction of the hydraulic Saw frame lowering, material positioning and the Pusher system is CNC controlled. The machines come standard with the environmentally friendly “B&S-Clean Cut cutting system” with minimal quantity lubrication equipped. This saves cleaning effort and is gentle Resources. CNC Control A CNC control allows programming of up to up to 90 cutting programs with different cut lengths, Quantities and mitres. The B&S pusher system, feeding and positioning system, is marked “on both sides “Opening gripping tongs” which are hydraulically controlled. This ensures safe gripping and transport of materials and Bundles that deviate slightly from the ideal shape. The pusher system is separate constructed and ground using ball-bearing linear guides Rack and guided by a frequency-driven, robust geared motor.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66244 · Band Saw - Automatic - Horizontal

BERG & SCHMID - K-tech 800 H - - - neu - -

Technical details

2-column band saw for quick cutting, K-tech 800H with pusher system P 15. P 30 (option), Fast, quiet and ergonomic cutting Special development for cutting profiles and beams as well as solid material. The material is fixed vertically on and section sides. The machine is from K-tech 800 H standard with an additional horizontal vice equipped. The interaction of the hydraulic Saw frame lowering, material positioning and the Pusher system is CNC controlled. The machines come standard with the environmentally friendly “B&S-Clean Cut cutting system” with minimal quantity lubrication equipped. This saves cleaning effort and is gentle Resources. CNC Control A CNC control allows programming of up to up to 90 cutting programs with different cut lengths, Quantities and mitres. The B&S pusher system, feeding and positioning system, is marked “on both sides “Opening gripping tongs” which are hydraulically controlled. This ensures safe gripping and transport of materials and Bundles that deviate slightly from the ideal shape. The pusher system is separate constructed and ground using ball-bearing linear guides Rack and guided by a frequency-driven, robust geared motor.

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66246 · Band Saw - Automatic - Horizontal

BERG & SCHMID - K-tech 60/48 CNC VS 500 - - - neu - -

Technical details

For miter cuts up to 45° left in fully automatic Operation and up to 60° left in semi-automatic operation Material height sensor (automatic cut start detection) Automatic feed unit via ball screw with incremental feed automatic length compensation Button on the saw band for automatic adjustment of the saw stroke Fully automatic control of the saw frame and clamping device Hydraulic unit with automatic pressure shut-off when idling Mechanical chip clearing brush feed vice opening on both sides Remaining piece length 100 mm Modern CNC control freely programmable for multiple sawing jobs with various Cutting lengths and quantities. Automatic feed unit 500 mm via ball screw incremental feed with automatic length compensation. Adjustable for section lengths of 25 – 9,999mm. Fully hydraulic control of saw frames and clamping devices Preselection of 3 different material feed speeds Visualization of the entire workflow with simple data entry

Datasheet

Request / Contact

Bandsaw - Horizontal

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66202 · Bandsaw - Horizontal

BERG & SCHMID - GBS 218 Eco AutoCut - - -NEU- -

Technical details

SPECIAL PRICE!!! -Miter cuts up to 60° left -Cutting speed 35 / 70 m / min. - Vice with quick release device -Carbide saw band guide -Tape tension control -Electr. automatic cooling Auto-Cut-System = 3 step system -Automatic saw frame lowering via the hydraulic cylinder -Infinitely adjustable feed -with limit switch - rapid lowering of the saw frame from the rest position to the workpiece, then switch to normal saw feed -Manual mode Share of freight costs 85 EUR

Datasheet

Request / Contact

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-66211 · Bandsaw - Horizontal

BERG & SCHMID - GBS 242 DG HA-I - - -Neu- -

Technical details

SPECIAL PRICE!!! Double miter metal band saw hydraulic semi-automatic with: - Hydraulic vice - Material height button - Cut monitoring by ammeter - Cutting pressure feed regulator - Belt speed 34 / 74 m/min - Miter cuts up to 60° left and 45° right - Patented, ball-bearing turntable for easy miter adjustment - Adjustable quick-release vise - Quick release lever - Automatic cooling Share of freight costs 120 EUR

Datasheet

Request / Contact

Perfil del comerciante: WMT GmbH & Co.kg

Contactar con el comerciante

WMT GmbH & Co.kg

Siemens carretera 1

46342 - Velen-Ramsdorf

Alemania

+ 49 2863 92477-47 "> + 49 2863 92477-47

+49 (2863) 92477-50

info@wmt.de

www.wmt.de

Siemens carretera 1

46342 - Velen-Ramsdorf

Alemania

+ 49 2863 92477-47 "> + 49 2863 92477-47

+49 (2863) 92477-50

info@wmt.de

www.wmt.de

Perfil del comerciante

Bienvenido a las máquinas herramientas WMT.

Compra y venta de máquinas herramientas nuevas y usadas.

Venta de equipos de taller.

Compra de maquinas herramienta usadas.

Procesamiento de resoluciones operativas.

Mediación de instalaciones completas de producción.

Comercio de máquinas-herramienta de cualquier tipo. ¿Estás buscando una máquina usada? Visítanos…

Sierra circular de aluminio Sierra de cinta Sierra de cinta - Sierra de cinta automática - Automática - Sierra de cinta horizontal - Sierra de cinta vertical - Sierra de cinta móvil Tipo de cama móvil Fresadora - Rectificadora de banda universal Máquina taladradora de banco Torno de banco - Torno automático de torno central Torno CNC - Cama inclinada fría Sierra circular Taladrado y fresado M / C Bridas y costura Máquina enrolladora Procesamiento de planchas y chapas Máquina plegadora Prensa manual Torno de alta resistencia Máquina de taladrado radial de alta velocidad Hydr. freno de la prensa Torno de la prensa hidráulica - controlado por ciclo Muesca de la máquina Perforadora de la prensa Pilar Máquina de perforación Máquina dobladora de tubos Cizalla de placa - Cizalla hidráulica de placa - Prensa neumática mecánica Máquina dobladora de perfiles Máquina de taladrado radial Rodillos / sistemas de parada Máquina dobladora de rodillos - 3 Rollos Mesa de soldadura rotativa Máquina afiladora de hoja de sierra Sección de corte Cizalla - Máquina combinada de trabajo de chapa de metal Torno de lecho deslizante Enderezadora - Máquina de esmerilado de superficie de doble columna Tipo de mesa Máquina de taladrado y roscado Prensa de palanca - Molinillo de herramientas de una sola columna - Herramienta de ajuste de herramientas universal Universal Tryout Press - hidráulico Universal Fresadora Embarcación Unidad de torneado Soldadura Humo Succión Soldadura Mesa Equipo de mesa de soldadura Soporte de ruedas Cajones de palet Transpaletas eléctricas Transpaletas manuales Carros de herramientas Carros de herramientas Banco de trabajo Sistema de estanterías Contenedor Carretilla elevadora - Eléctrico Material pesado Remolque Trailer Mesa elevadora Imán de carga Máquina de chorro de arena Placa de plato Chuck Sujeciones Sujeción Chuck Sujeción de la mesa Placa transversal de la mesa Placa rotativa Lynette

WMT GmbH & Co.KG

Siemens carretera 1

46342 Velen-Ramsdorf

FON: + 49 2863 92477-47

FAX: + 49 2863 92477 50

Correo electrónico: info@wmt.de

WMT GmbH & Co.kg

Siemensstraße 1

Contact Trader

WMT GmbH & Co.kg

Siemensstraße 1

46342 - Velen-Ramsdorf

Deutschland

+49 2863 92477-47

+49 2863 92477-50

info@w-m-t.de

www.w-m-t.de

Contact person:

Siemensstraße 1

46342 - Velen-Ramsdorf

Deutschland

+49 2863 92477-47

+49 2863 92477-50

info@w-m-t.de

www.w-m-t.de

Contact person:

Machine category

Abkantpresse - hydraulisch · Abricht- und Dickenhobel · Alu-Kreissäge · Aufspanntisch · Ausklinkmaschine · Bandschleifmaschine · Bandsäge - horizontal · Bandsäge - Vertikal · Bandsäge mobil · Bandsägeautomat - Horizontal · Behälterdrehvorrichtung · Bettfräsmaschine - Vertikal · Biegemaschine horizontal · Blechbearbeitungsanlagen · Blechbiegemaschine - 3 Walzen · Blechbiegemaschine - 4 Walzen · Bohr- und Fräsmaschine · Bohrerschleifmaschine · Bügelmesschraube · Bügelsäge · Bügelsäge - Automatisch · Bürstenentgrater · Doppel-Gehrungsäge · Doppelschleifbock · Drehmaschine - zyklengesteuert · Drehmeißel/Drehstahl · Einständerpresse - Hydraulisch · Flachschleifmaschine · Flachstahl- / Plattenbearbeitung · Fräsmaschine - Horizontal · Fräsmaschine - Universal · Gabelhubwagen - Elektro · Gabelhubwagen Elektro · Gabelhubwagen Hand · Gabelstapler Diesel · Gabelstapler Elektro · Gabelstapler Gas · Generatoren · Gewindebohrmaschine · Gewindeschneidmaschine · Gleitschleifanlage · Handhebelpresse · Handwerkzeuge · Hubtische · Kaltkreissäge · Kaltkreissäge - Automatik · Kapp- und Gehrungssäge · Kniehebelpresse - Einständer · Kombi-Schleifmaschine · Kompressoren · Krananlagen · Kreissäge · Kreuztisch · Kühlmittelanlage · Langgutregale · Lasthebemagnete · Leit- und Zugspindeldrehmaschine · Lochstanze - Einständer · Magnetbohrmaschine · Magnetspannplatte · Maschinen Untergestell · Maschinenleuchten · Messerschleifmaschine · Plasmaschneidegerät · Pneumatische Presse · Polierbock · Profil- Ring- Biegemaschine · Profilstahlschere - Kombiniert · Punktschweißmaschine · Regalsysteme · Reinigungssysteme · Richtpresse - Doppelständer · Rohrausschleifer · Rohrbiegemaschine · Rollenbahnen / Anschlag-Systeme · Räumnadeln · Schnellradiale - Bohrmaschine · Schraubenkompressor · Schraubstock · Schubladenschränke · Schweißanlage · Schweißdrehtisch · Schweißdrehtisch - rund · Schweißkantenabschrägmaschine · Schweißrauchabsaugung · Schweißtisch · Schweißtisch-Zubehör · Schweißzubehör · Schwenkbiegemaschine · Schwerlastanhänger · Sicken- und Bördelmaschine · Sonstige Fördertechnik · Sonstiges · Strahlanlage · Stähleschleifmaschine · Ständerbohrmaschine · Sägeblattschärfmaschine · Säulenbohrmaschine · Tafelschere - hydraulisch · Tafelschere - mechanisch · Teilapparat · Tischbohrmaschine · Tischbohrwerk · Tischdrehbank · Trowalisiermaschine · Unterstellbock · Wasserpumpe · Werkbänke · Werkstattpressen - hydraulisch · Werkzeugaufnahme · Werkzeugfräsmaschine - Universal · Werkzeugschränke · Werkzeugwagen ·