EMUK GmbH Werkzeugmaschinen Spezialist für Verzahnungsmaschinen - Stockist for used machines

Machinelist:

Gear Hobbing Machine - Vertical

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24054 · Gear Hobbing Machine - Vertical

PFAUTER - P 630 - - 2000 -

Technical details

Chip conveyor, change gears, arbors, toolings.

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23238 · Gear Hobbing Machine - Vertical

HURTH-MODUL - WF 315 S - - 1998 - 840C Siemens

Technical details

Siemens Sinumerik 880 M - control partial gearbox double threaded, automatic workpiece feeding, conversational programm Video link: https://www.youtube.com/watch?v=GkQs8lfeNYk

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24153 · Gear Hobbing Machine - Vertical

GLEASON- PFAUTER - PE 1200/1600 - - 1997 - Siemens 840 C

Technical details

Sonderfräskopf M2 - Max Fräserdurchmesser 350 mm - Max Fräserlänge 375 mm - Max Fräserverschiebung 300 mm

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23076 · Gear Hobbing Machine - Vertical

WMW-MODUL - ZFWZ 400/4 - - 1985 -

Technical details

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23059 · Gear Hobbing Machine - Vertical

WMW-MODUL - ZFWZ 250/5 - - 1982 -

Technical details

Datasheet

Request / Contact

Gear Shaping Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24154 · Gear Shaping Machine

LORENZ - SN 4 - - ca 1981 -

Technical details

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23230 · Gear Shaping Machine

LORENZ - SN 4 - - ca 1981 -

Technical details

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-E23259 · Gear Shaping Machine

GLEASON- PFAUTER - P 1200 S - - 2008 - Siemens 840D Powerline

Technical details

Gleason-PFAUTER CNC gear shaping machine P 1200 S for the production of internally and externally cylindrical gears with internal and external teeth and other rolling profiles and moulds profiles and moulds that regularly occur on the cylindrical workpiece circumference and for the production of profiles in the single part process. Special version with hydraulic shaping head H1 SCOPE OF EQUIPMENT: - Basic machine P1200S, Siemens 840D Powerline (XP) - Hydraulic shaping head H1 - Signal light (3-colour) - Extended software for fault diagnosis - Telephone diagnosis system - Chip disposal through table bore - Set of adjusting wedges - Monitoring devices - Warm-up programme - Network connection (Ethernet) - 19" flat control panel OP 015A - Offline version "dialogue programming - Vapour separator make "3nine" type KLARA - Machine installation under floor - Rinsing gun - Mounting device - Cutting wheel holder ( 3 pieces ) - Cutting wheel holder for sheep cutting wheels - Cutting wheel holder for sheep cutting wheels - Special cutting wheel holder - Preparation for retrofitting paper belt filter system - Measuring device for machine P 1200 S - Clamping base body - BDE/MDE interface in the machine control cabinet Modification of vapour separator make "3nine" type Klara type EMMA Working range and technical data: Nominal workpiece diameter External toothing. . . . . . . . 1.200 mm Internal gearing. . . . . . . . 1.200 mm Largest workpiece circulation Ø without counter stand... 1.400 mm Nominal machine module approx. - with hydraulic impact head H1... 16 mm Shaping spindle stroke rate range - with hydraulic shaping head H1 max. 80 min-1 Largest toothing width - with hydraulic shaping head H1... 350 mm Smallest pitch height of the hydrostatic screw guide - with hydraulic shaping head H1... 850 mm Smallest/largest distance between tool and workpiece axis - with hydraulic shaping head H1... 0 - 750 mm Axial slide adjustment range - with hydraulic shaping head H1... 1.100 mm Lowest shaping spindle position above table with hydraulic shaping head H1 ** with upper position Shaping stroke... 560 mm Column side offset range - with hydraulic pusher head H1... +/- 50 mm Mould mounting cone - with hydraulic shaping head H1 - HSK-80(hollow shank taper according to DIN 69063) Workpiece with external gearing: - Module max. 16 mm, - max. toothing width 350 mm, - max. external Ø 1.200 mm, Workpiece with internal gearing: - Module max. 16 mm, - max. toothing width 350 mm, - max. circulation Ø 1.400 mm, - max. internal Ø 1.200 mm, - max. shaping wheel Ø 260 mm, - Mounting in shaping spindle HSK-80, - Slide travel; X/Y/Z- 750 /100 / 1.100 mm, Workpiece table: - Outer Ø 1.200 mm, - bore 300 mm, - max. load 150 kN, - Cooling unit, Küma, type OWT600-3KK, year 2008, - Hydraulic unit, manufactured by Parka, - Centrifuge, made by Steimel, - Air filter, Indusa, type EL4001NTDASECL/O, version AOO, max. air capacity 4.000 m³/h

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24003 · Gear Shaping Machine

GLEASON-Pfauter - GP 130 S - - 2005 - Siemens 840 D

Technical details

Counterhold without center hydraulically operated counter arm and Linear guides. For automatic ring loader, with 4 stations

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24013 · Gear Shaping Machine

LORENZ - LS 304 CNC - - 1991 -

Technical details

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24136 · Gear Shaping Machine

LORENZ - LS 424 - - 1989 - BWO CNC

Technical details

Machines increase 100 mm intermediate plate automatic Hublageverstellung automatic Hublängeverstellung 5 axis controlled machine BWO last type C, D, X, Z, L axes are CNC

Datasheet

Request / Contact

Gear Testing Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23114 · Gear Testing Machine

PFAUTER - Zahnräder / Wechselräder P 251 - - unbekannt -

Technical details

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

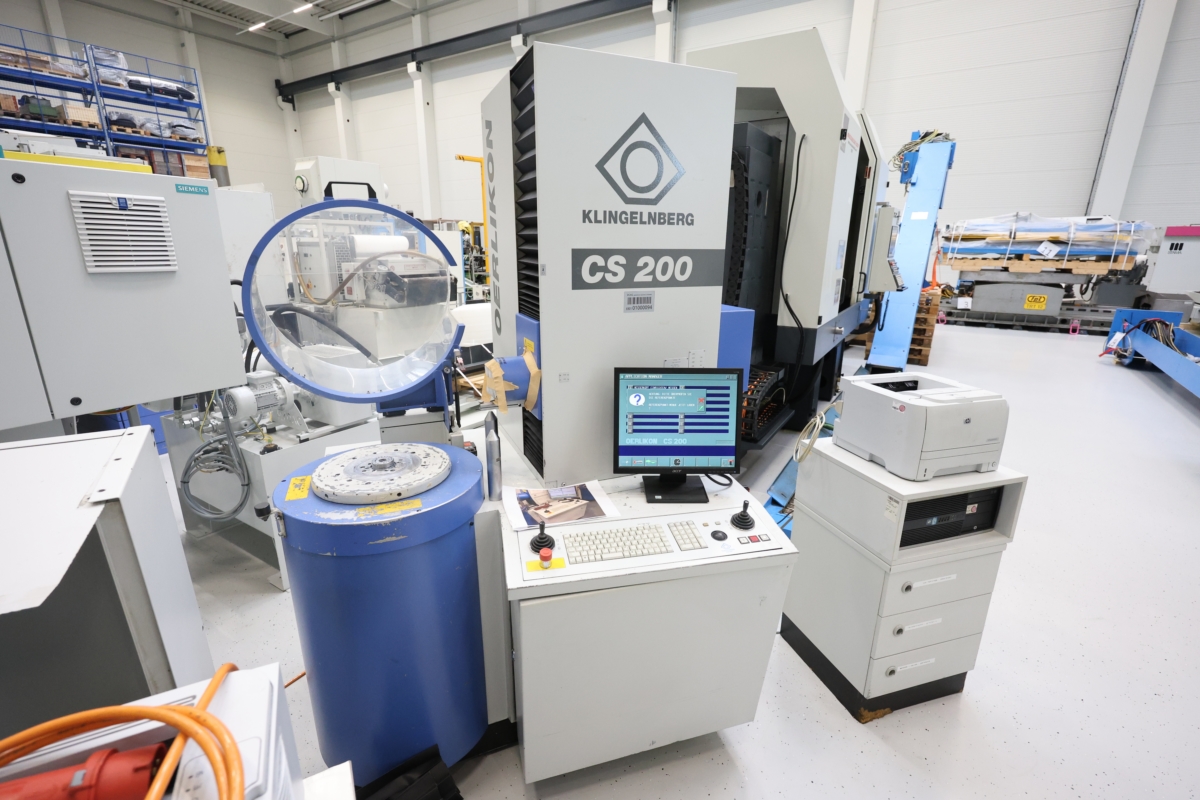

#1058-23251 · Gear Testing Machine

KLINGELNBERG-OERLIKON - CS 200 - - 2004 -

Technical details

In the manufacturing process for spiral-toothed bevel gears, the quality of the gear cutting gear cutting tools used plays a decisive role. Particularly in high gear cutting quality and a long service life can only be achieved with precisely can only be achieved with precisely adjusted cutterheads. The Oerlikon cutterhead setting and testing device CS 200 enables quick and easy setting of the individual knives and simple adjustment of the individual knives, it checks the position and documents the measurement results. The measuring sequence on the CNC-controlled testing device is partially automated: The individual actions for carrying out the actions for carrying out the sequence are displayed on the screen via the operator guidance. The positioning of the individual knives in the cutter head and the height of the knife tips is largely automatic thanks to a special sequence and is simultaneously documented by means of a run-out diagram. A subsequent measuring sequence checks the radial position of the inner and outer cutting edges of all knives in the cutterhead. If individual test parameters on the knives do not correspond to the the tolerance specifications, this can be individually repositioned. The combination of semi-automated setting sequence, operator-guided set-up actions and automatic operator-guided set-up actions and automatic measuring sequence, cutterheads can be can be set conveniently, quickly and with high precision. Operator-guided setting and test sequence - Graphic display of the cutter head design and the measurement results with tolerance check - Instructions for the operator in plain text Instructions for the operator in plain text (without coded information) - Simple assignment of the measurement results to the knives - Documentation of the setting and measurement results via printer- Setting and test sequence suitable for ARCON®, RSR, Spirapid, SPIRON®, TRI-AC® types - Interface for neutral data

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23250 · Gear Testing Machine

KLINGELNBERG-OERLIKON - CS 200 - - 2002 -

Technical details

In the manufacturing process for spiral-toothed bevel gears, the quality of the gear cutting gear cutting tools used plays a decisive role. Particularly in high gear cutting quality and a long service life can only be achieved with precisely can only be achieved with precisely adjusted cutterheads. The Oerlikon cutterhead setting and testing device CS 200 enables quick and easy setting of the individual knives and simple adjustment of the individual knives, it checks the position and documents the measurement results. The measuring sequence on the CNC-controlled testing device is partially automated: The individual actions for carrying out the actions for carrying out the sequence are displayed on the screen via the operator guidance. The positioning of the individual knives in the cutter head and the height of the knife tips is largely automatic thanks to a special sequence and is simultaneously documented by means of a run-out diagram. A subsequent measuring sequence checks the radial position of the inner and outer cutting edges of all knives in the cutterhead. If individual test parameters on the knives do not correspond to the the tolerance specifications, this can be individually repositioned. The combination of semi-automated setting sequence, operator-guided set-up actions and automatic operator-guided set-up actions and automatic measuring sequence, cutterheads can be can be set conveniently, quickly and with high precision. Operator-guided setting and test sequence - Graphic display of the cutter head design and the measurement results with tolerance check - Instructions for the operator in plain text Instructions for the operator in plain text (without coded information) - Simple assignment of the measurement results to the knives - Documentation of the setting and measurement results via printer- Setting and test sequence suitable for ARCON®, RSR, Spirapid, SPIRON®, TRI-AC® types - Interface for neutral data

Datasheet

Request / Contact

Spiral Bevel Gear Cutting Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-18018 · Spiral Bevel Gear Cutting Machine

KLINGELNBERG - C 28 P - - 2002 - 840 C Siemens

Technical details

Datasheet

Request / Contact

Worm gear tester

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-EWH821 · Worm gear tester

KLINGELNBERG - PS 750 - - ca.1995 -

Technical details

Datasheet

Request / Contact

Worm Milling Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24151 · Worm Milling Machine

GLEASON- PFAUTER - P90WM - - 2009 - Siemens 840D

Technical details

Worm milling head with toothed belt drive. With infinitely variable high-performance drive and maintenance-free bearing. Spindle with hollow shank taper for holding milling arbor with counter bearing. - Workpiece spindle with direct and maintenance-free drive. Equipment: - CNC Siemens 840D - Cooling tank - chip conveyor Product data : - Diameter : 100 mm - Nominal module * hobbing : approx. 3.0 mm * Endless screw milling : approx. 5.0 mm - Max. axial movement : 320 mm - Cutting head orientation : -45 / + 115 ° - Main milling cutter max. diameter : 118 mm - Max. Max. cut-out length of the post cutter : 180 mm - Max. Mill movement ( shifting) : 160 mm - Max. Spindle speed of the workpiece carrier : 3000 t/mm - Min./max. distance between axes : 10/100 mm - Cutting head motor power : 14 kW - Main milling speed : 50-12000 t/mm - Weight : 5000 kg

Datasheet

Request / Contact

Cylindrical Grinding Machine - Universal

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23201 · Cylindrical Grinding Machine - Universal

KARSTENS - ASA 16A/ 400 - - 1966 -

Technical details

Datasheet

Request / Contact

Edge Grinding Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-20088 · Edge Grinding Machine

CHRISTEN - KB 2 - - unbekannt -

Technical details

Edge-breaking machine

Datasheet

Request / Contact

Polishing Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23138 · Polishing Machine

EIGENBAU - 2 - - unbekannt -

Technical details

175 €

Datasheet

Request / Contact

Rotary Table Grinding Machine - Vertical

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-E23268 · Rotary Table Grinding Machine - Vertical

GEIBEL & HOTZ - RT 1000 CNC - - 2009 - Siemens 840D

Technical details

- max. grinding area Ø 800 x 500 mm, - Magnetic discs Ø 800 mm, - Table load max. 1,000 kg, - max. sanding spindle speed 3,150 1/min, - max. transverse movement 600 mm, - Cup wheel Ø max. 300 mm, - max. width 80 mm, mounting hole 127 mm, - control, Siemens, with - filter unit, Knoll, type HL250/2000,

Datasheet

Request / Contact

Drill Grinding Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23136 · Drill Grinding Machine

Klingel - BSM 80 - - -

Technical details

Datasheet

Request / Contact

Milling Graver Grinding Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24071 · Milling Graver Grinding Machine

FEINMECHANIK DECKEL - S0E/70 - - ca. 1976 -

Technical details

Datasheet

Request / Contact

Tool and Cutter Grinder

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24068 · Tool and Cutter Grinder

Hahn&Kolb - WS 54 - - ca. 1985 -

Technical details

Datasheet

Request / Contact

Emuk GmbH Werkzeugmaschinen Spezialist Für Verzahnungsmaschinen

Siemensstrasse 24 a

Contact Trader

Emuk GmbH Werkzeugmaschinen Spezialist Für Verzahnungsmaschinen

Siemensstrasse 24 a

76316 - Malsch

Deutschland

+49 (0) 7246 1392

+49 (0) 7246 1394

info@emuk.de

www.emuk.de

Contact person:

Die EMUK GmbH ist ein international tätiges Unternehmen für den Handel mit gebrauchten Werkzeugmaschinen. Seit über 40 Jahren exportieren und importieren wir Werkzeugmaschinen weltweit.Wir sind spezialisiert auf den Handel mit gebrauchten Verzahnungsmaschinen der Marken Pfauter Lorenz, Reishauer, Köpfer und vielen weiteren Fabrikaten.

Wir haben auf 3.000 qm ständig Maschinen vor Ort; gerne können Sie uns kontaktieren.

Siemensstrasse 24 a

76316 - Malsch

Deutschland

+49 (0) 7246 1392

+49 (0) 7246 1394

info@emuk.de

www.emuk.de

Contact person:

Die EMUK GmbH ist ein international tätiges Unternehmen für den Handel mit gebrauchten Werkzeugmaschinen. Seit über 40 Jahren exportieren und importieren wir Werkzeugmaschinen weltweit.Wir sind spezialisiert auf den Handel mit gebrauchten Verzahnungsmaschinen der Marken Pfauter Lorenz, Reishauer, Köpfer und vielen weiteren Fabrikaten.

Wir haben auf 3.000 qm ständig Maschinen vor Ort; gerne können Sie uns kontaktieren.

Machine category

Abläng- und Zentriermaschine · Absaugung · Abwälzfräs- und Stoßmaschine -kombiniert · Abwälzfräser · Anreißplatte · Aufspannwinkel · Ausklinkmaschine · Auswuchtmaschine · Bandsäge - Automatisch · Bearbeitungszentrum - Vertikal · Bohrer · Bohrerschleifmaschine · CNC Drehmaschine · Drahterodiermaschine · Drehmaschine - zyklengesteuert · Drehmaschine-konventionell-elektronisch · Entgratmaschine · Ersatzteile · Filteranlage · Fixatoren · Fräs- und Drehwerkzeuge · Fräskopf senkrecht · Fräsmaschine - Universal · Fräsmaschine - Vertikal · Frässtichel-Schleifmaschine · Futter · Förderband · Gewinde-Schnecken-Schleifmaschine · Gewindebohrmaschine - Vertikal · Gewindewalzmaschine · Honmaschine - Innen - Horizontal · Hydraulikaggregat · Härteprüfer · Kantenfräsmaschine · Kantenschleifmaschine · Kegelrad - Läppmaschine · Kegelrad-Prüfmaschine · Kegelradfräsmaschine-Bogenverzahnung · Kegelradhobelmaschine · Kippvorrichtung · Kniehebelpresse - Einständer · Kompressor · Koordinatenmessmaschine · Kühlmittelanlage · Langgewinde- und Abwälzfräsmaschine · Leit- und Zugspindeldrehmaschine · Messerkopf · Messmaschine · Meßmittel · Motor · Nuten-Stossmaschine · Nutenziehmaschine · Planscheibe · Polierbock · Prägepresse - Einständer - hydraulisch · Pumpenaggregat · Radialbohrmaschine - transportabel · Reitstock · Richtpresse - Horizontal · Rundschleifmaschine - Universal · Rundtaktmaschine · Rundtischflachschleifmaschine - Vertikal · Räumnadeln · Schleif- und Läppmaschine · Schleifscheibenflansch · Schneckenfräsmaschine · Schneckenradprüfmaschine · Schraubenkompressor · Schraubstock · Schweißanlage · Schwenkbiegemaschine · Spannfutter · Spannmittel · Spiralkegelradschneidmaschine · Stoßmaschine - Vertikal · Ständerbohrmaschine · Sägezentrum · Tafelschere - hydraulisch · Tafelschere - mechanisch · Teilapparat · Transformator · Vertikal - Stoßmaschine · Verzahnungsmeßmaschine · Werkzeug Voreinstellgerät · Werkzeugaufnahme · Werkzeugfräsmaschine - Universal · Werkzeughalter · Werkzeugschleifmaschine · Werkzeugschrank · Wälzfräser · Zahnrad-Abwälzfräsmaschine - horizontal · Zahnrad-Abwälzfräsmaschine - vertikal · Zahnradschleifmaschine · Zahnradstossmaschine · Zahnstangenfräsautomat · Zubehör · Zweiflanken-Wälzprüfmaschine · Ölkühlgerät · Ölnebel-Abscheider ·