Amann Werkzeugmaschinen GmbH - Stockist for used machines

Machinelist:

Center Lathe

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17988 · Center Lathe

WEILER - Matador VS2 - - 1982 -

Technical details

Chuck protection device with electrical switch-off Tool cabinet with various contents

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17987 · Center Lathe

WEILER - Matador VS2 - - 1982 -

Technical details

Chuck protection device with electrical switch-off Tool cabinet with various contents

CNC Lathe

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17367 · CNC Lathe

WEISSER - Univertor AS 400 - - 2008 - Siemens 840 D

Technical details

CNC lathe with SIEMENS SINUMERIK 840D control; Screw conveyor with chip breaker and return pumping station; NC-steady SMW-SLU-1-OLD Ø10-70mm; 12-fold tool turret SAUTER 0.5.460.220; NC tailstock; Artis monitoring; Pickup-loading incl. conveyor. Without coolant system, was connected to central supply. Machine can be inspected under power.

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17366 · CNC Lathe

WEISSER - Univertor AS 400 - - 2008 - Siemens 840 D

Technical details

CNC lathe with SIEMENS SINUMERIK 840D control; Screw conveyor with chip breaker and return pumping station; NC-steady SMW-SLU-1-OLD Ø10-70mm; 12-fold tool turret SAUTER 0.5.460.220; NC tailstock; Artis monitoring; Pickup-loading incl. conveyor. Without coolant system, was connected to central supply. Machine can be inspected under power.

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17957 · CNC Lathe

INDEX - G 300 - - 1996 - C200 - 4

Technical details

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

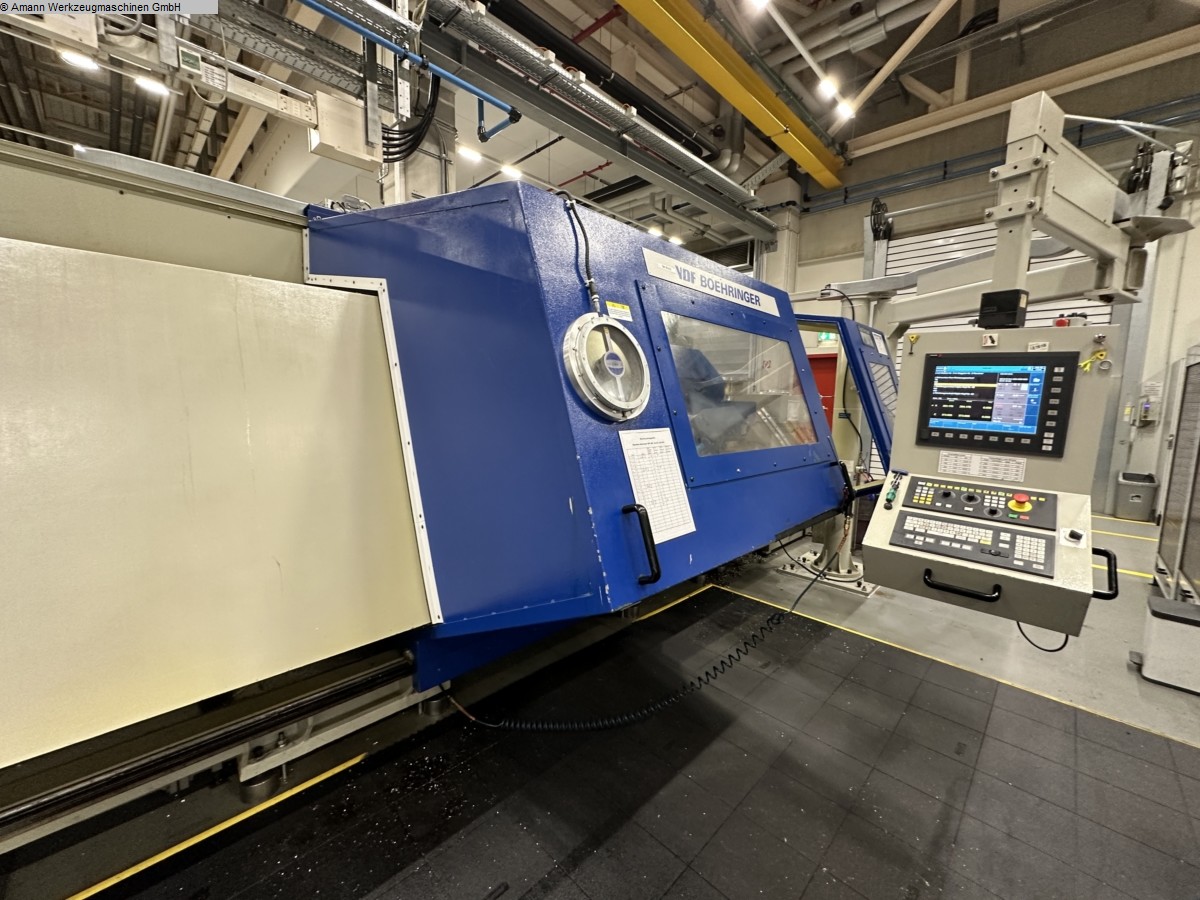

#1006-17997 · CNC Lathe

VDF BOEHRINGER - V800 NC II - - 1990/2011 - FAGOR 6065

Technical details

Machine was completely overhauled in 2011 3-jaw wedge bar chuck Forkardt Ø630 with various clamping jaws Main spindle with 4 gear stages and indexing device 12-fold disc turret with 6-fold tool drive VDI50 4-fold revolver Sauter Tailstock with hydr. Quill various tool holders VDI50 / prism cassettes Rotating viewing window Visi-Door chip conveyor Coolant device

CNC Turning- and Milling Center

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17959 · CNC Turning- and Milling Center

MORI SEIKI - NTX1000 - - 2012 - MSX-711-IV Mori Seiki

Technical details

MAPPS control system Renishaw HPRA (manual tool presetter) Blum Laser Control Direct measuring system X;Y;Z;B Collet chuck SMW Autoblok KSZ-MB-040-Z140 Workpiece conveyor belt Bar feeder Breuning Irco ILS-RBK-10012 Knoll band filter KF10/500 / IKZ with milling spindle 7 stages up to 70 bar Chip conveyor ConSep 2000

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17898 · CNC Turning- and Milling Center

INDEX - G200 - - 2007 - C200-4D INDEX

Technical details

Main (S3) and counter spindle (S4) with tailstock function hydraulic clamping cylinders in the main and counter spindle S3 spindle 42mm/13kW/7000 rpm S4 spindle 42mm/13kW/7000 rpm (electric shaft) S1;S2;S3;S4 as C axis 2 tool breakage sensors Turret 1 (X1;Y;Z1) with 14 stations / driven / VDI25 Turret 2 (X2;Z2) with 14 stations / powered / VDI25 Z4 axis counter spindle Z5 axis portal removal device Index conveyor belt 1 Transmit / Tracyl in CH1/CH2 Hainbuch collet system UNIMAG interface Short bar loader Breuning IRCO RBK 10012 built in 2007 chip conveyor Coolant device

Facing Lathe

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17807 · Facing Lathe

SEIGER - SPL-CG1400 - - 2018 - ManualPlus 620

Technical details

HEIDENHAIN ManualPlus 620 Hydraulic power clamping device 3-jaw chuck SMW Autobloc Ø 1000 mm 4-fold steel holder PARAT "manual"

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17806 · Facing Lathe

SEIGER - REKORD CG1400 - - 2009 - ManualPlus 620

Technical details

4-fold steel holder PARAT "manual" Manually operated faceplate ROEHM 4 jaws Ø 1000 mm

Lathe - cycle-controlled

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-52766 · Lathe - cycle-controlled

GILDEMEISTER - NEF Plus 710 - - 1996 - Manual Plus 3110 Heidenhain

Technical details

Vertical Turning Machine

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17847 · Vertical Turning Machine

WEISSER - Vertor M1 - - 2012 - SINUMERIK 840 D

Technical details

Equipment List attached

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-18018 · Vertical Turning Machine

FAMAR - Ergo400 - - 2009 - SIEMENS 840 D

Technical details

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17859 · Vertical Turning Machine

EMAG - VTC 250 DUO - - 2008 - SIN840 PL

Technical details

Bench Drilling Machine

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

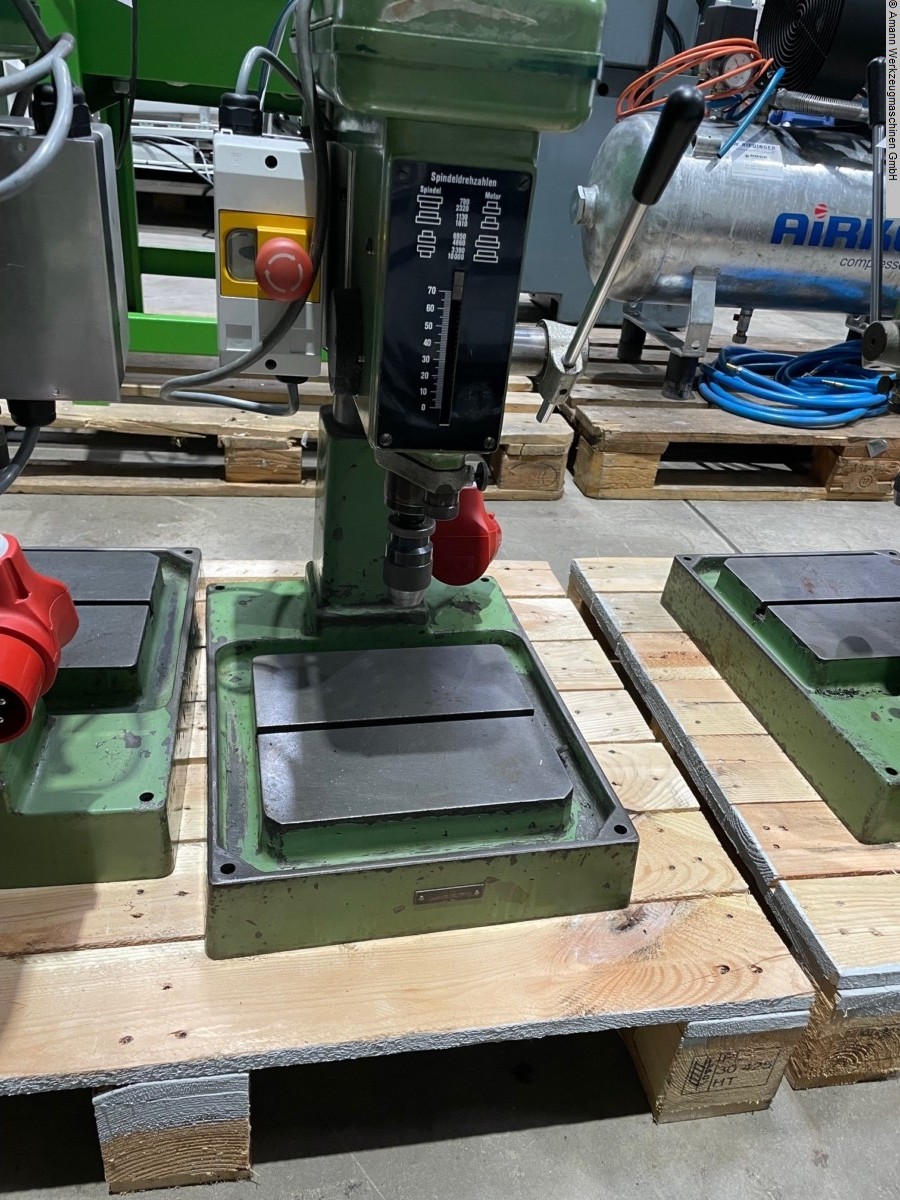

#1006-17986 · Bench Drilling Machine

WÖRNER - B8 - - 1986 -

Technical details

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17984 · Bench Drilling Machine

WÖRNER - B8 - - 1986 -

Technical details

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17985 · Bench Drilling Machine

WÖRNER - B8 - - 1986 -

Technical details

Machining Center - Horizontal

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17832 · Machining Center - Horizontal

HÜLLER-HILLE - BLUESTAR 5 - - 2005 - SIN 840 D SIEMENS

Technical details

Horizontal machining center with SIEMENS SIN840D (PCU50); chip conveyor, coolant-unit, coolant throu the spindle 40bar at 23 l/min;

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17833 · Machining Center - Horizontal

HÜLLER-HILLE - BLUESTAR 5 - - 2005 - SIN 840 D SIEMENS

Technical details

Horizontal machining center with SIEMENS SIN840D (PCU50); chip conveyor, coolant-unit, coolant throu the spindle 40bar at 23 l/min;

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17993 · Machining Center - Horizontal

MAKINO - a81-A137 c - - 2005 - FANUC Pro-3

Technical details

Horizontal machining center with FANUC Porfessional 3 control, chip conveyor, BLUM measuring probe, through-spindle coolant, 137-station tool magazine, electronic handwheel. Without coolant filter, was connected to center supply.

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17992 · Machining Center - Horizontal

MAKINO - a81-A137 d - - 2005 - FANUC Pro-3

Technical details

Horizontal machining center with FANUC Porfessional 3 control, chip conveyor, BLUM measuring probe, through-spindle coolant, 137-station tool magazine, electronic handwheel. Without coolant filter, was connected to center supply.

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17750 · Machining Center - Horizontal

HÜLLER HILLE - NBH 170 - - 2003 - SIN840D

Technical details

Horizontal machining center with SIEMENS SIN840D control. NC-rotary table; chip conveyor; coolant-unit; coolant through the spindle Magazine with 2 cassette à 50 pockets.

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17919 · Machining Center - Horizontal

OKUMA - MA50HB - - 2001 - OKUMA OSP U-100M

Technical details

Horizontal machining center with OKUMA OSP U-100M control; electron. hand wheel; pallet changer; coolant system

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17586 · Machining Center - Horizontal

HELLER - MC26 - - 2000 - SIN 840D

Technical details

Horizontal machining center with SIEMENS SIN840D control; Coolant unit KNOLL; chip conveyor, coolant through the spindle 50bar;

Perfil del comerciante: Amann Werkzeugmaschinen GmbH

Contactar con el comerciante

Landshut carretera 1

85716 - Unterschleißheim

Alemania

(0049) 89 317754 0 "> (0049) 89 317754 0

(0049) 89 3174262

info@amann-wzm.de

www.amann-wzm.de

Perfil del comerciante

Amann se fundó en 1969 y, a lo largo de los años, se ha desarrollado desde una pequeña empresa hasta convertirse en uno de los distribuidores de máquinas-herramienta más conocidos y confiables de Alemania.

En 1988, construimos nuestras salas de producción y oficinas actuales en el norte de Munich. Hoy en día, en un área de exhibición de más de 5,000 m2, más de 500 premium de segunda mano y nuevas maquinas automáticas están disponibles para nuestros valiosos clientes en todo momento. Una expansión en tamaño y rango que nos ha permitido no solo servir al campo tradicional europeo, sino también al ambicioso y aún próximo mercado asiático. Nuestros clientes locales, regionales e internacionales valoran mucho nuestras máximas de altos estándares de calidad, fiabilidad alemana, servicios de alta calidad y precios justos por más de 40 años.

Los contactos extensos con la industria a gran escala nos permiten encontrar casi cualquier herramienta de máquina para usted. Nuestro servicio especial: El servicio de búsqueda de Amann: con él, incluso las consultas de búsqueda altamente especializadas están en buenas manos con nosotros. Todo esto nos convierte en un socio eficiente, que opera a nivel internacional y satisface todas sus necesidades y deseos en el trabajo del metal.

Los contactos extensos con la industria a gran escala nos permiten encontrar casi cualquier herramienta de máquina para usted. Nuestro servicio especial: El servicio de búsqueda de Amann: con él, incluso las consultas de búsqueda altamente especializadas están en buenas manos con nosotros. Todo esto nos convierte en un socio eficiente, que opera a nivel internacional y satisface todas sus necesidades y deseos en el trabajo del metal.

¡Descubre las ventajas de trabajar con Amann!

Amann es una de las principales direcciones para la mayor eficiencia económica. Especialmente para la industria automotriz (OEM y proveedores), aeroespacial, tecnología médica, fabricación de transmisiones, producción de bolas / rodamientos, ingeniería mecánica y tecnología de medición / control. Nuestra línea completa de productos abarca desde máquinas-herramienta convencionales hasta máquinas controladas por CNC. Tenemos en stock todas las máquinas (usadas y nuevas) que son esenciales para su producción: desde tornos, fresadoras, rectificadoras, máquinas cortadoras de engranajes, prensas, centros de mecanizado, máquinas de perforación y líneas completas de producción de cigüeñales hasta máquinas de procesamiento de chapa, como cizallas para placas. Frenos de prensa, máquinas dobladoras de rodillos, máquinas láser, punzonadoras, máquinas de pulido, y muchos más.

Además, somos expertos en la distribución de líneas de fabricación complejas y en instalaciones operativas completas. Nuestras máquinas herramienta de segunda mano llevan los nombres de fabricantes de renombre como: Aba, Amada, Boeringer, DMG, Doerries, Durma, EHT, Elb, Gleason, Hurth, Ingersoll, Jung, Klingenberg, Liebherr, Lorenz, LVD, Matec, Mazak, Mori Seiki, Müller-Weingarten, Nosstek, Oerlikon, Pfauter, Reisshauer, Schaudt, Schieser, Schuler, Studer, Soraluce, Timesaver, TOS, Trumpf, Schuler, Union, Weiler, Weinbrenner, WFL y Wotan ..

| Oficina y almacén Landshuter Str. 1 - 85716 Unterschleissheim / Muenchen Alemania | |

| Teléfono +49 (89) 317754-0 | |

| Fax +49 (89) 317754-99 | |

| Correo electrónico Todas las consultas y ofertas para: info@amann-wzm.de | |

| Sr. Bobe Gerente general | |

| Señora amann Firmante autorizado | |

| Sr. Haertl Gerente de Ventas Europa / Africa | |

| Sr. Berchner Gerente de Ventas Medio Oriente / Asia | |

| Sr. Nagel Gerente de Ventas Medio Oriente / Asia | |

| Señora krappel Asistente de ventas | |

| Señora juelicher Asistente de ventas |

Landshuter Straße 1

Contact Trader

Landshuter Straße 1

85716 - Unterschleißheim

Deutschland

(0049) 89 317754 0

(0049) 89 3174262

info@amann-wzm.de

www.amann-wzm.de

Contact person:

Herrn Alois Kindermann 08931775420

Auf 5000 m² Ausstellungsfläche stehen ständig mehr als 500 moderne gebrauchte Werkzeugmaschinen für unsere Kunden zu Verfügung.