Internal and Face Grinding Machine

Machinelist: Internal and Face Grinding Machine

Internal and Face Grinding Machine

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-0000289 · Internal and Face Grinding Machine

JOTES - SOJ 10M - - Überholt -

Technical details

100 % before loading warranty: none one used internal grinding machine, make: Jotes, type: SOJ 10M, year of produktion 1986

Datasheet

Request / Contact

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-93810 · Internal and Face Grinding Machine

Robbi - IGR 600 - - Fabrikneu - Siemens 840 D oder SPS von Sie

Technical details

PERFORMANCE AND PRECISION DEGREE Robbi grinding machines are according to the international precision normes ISO 2433. The table movement linearity is guaranteed by a max. deviation of 0,002 mm/mt. The obtainable grinding roundness is : 0,4m (**) (**) for a test workpiece ground in our factory during machine testing The CNC controls : Wheel head movement (AXIS X) Longitudinal table movement (AXIS Z) Work head spindle rotation speed The available programs permit the programming of the following grinding cycles Plunge Cylindrical pass Cylindrical pass with interpolation between table and wheel movement to grind taper workpieces Radius The software for the workpiece grinding operation is very simple and intuitive. To facilitate the programming the software is equipped with an exemplifying graphics, to input the data for each parameter. The software, has been specially studied, so as to permit also non specialised operators to programme without any problems complex workpieces. When the workpiece grinding programme has been completed the CNC will automatically make up a summary list, where only the geometric parameters are evidenced. This list permits with a glance to verify the complete programme; this operation is very helpful to verify eventual input data errors or to check rapidly a workpiece programme when reloaded from the file. While the programme is in execution, it is possible to intervene and modify in real time the technologic parameters, such as: increments, dwell inversion times, sparkout passes. Also, it is possible to intervene with the jog handwheel. The Grinding Machine is composed of : BASE Structure in normalised and stabilised cast iron with large ground guides. The lubrication plant supplies a constant oil flow distributed over the complete length of the guides. In the middle of the base, there is positioned the ball screw for the table longitudinal movement. On all the lower part of the perimeter are situated the recesses for machine levelling. Considering the base structure, usually a foundation is not required. TABLE The table is manufactured in two parts, both are in normalised and stabilised cast iron. The lower part is composed of wide guides which are ground and accurately hand scrapped, for a better sliding. The upper part, is swivelable in the two directions, suitable for grinding tapered workpieces. It includes a micrometric device with centesimal dial gauge for taper control. WORKHEAD The structure in normalised, stabilised and well ribbed cast iron, allows to support the workpiece weight and the force generated by the grinding operation. The spindle rotates on high precision ball bearings, guaranteeing restricted tolerance and maximum rigidity in the working. The spindle rotation is by means of a three phase motor with variable speed controlled by an inverter. INTERNAL GRINDING SPINDLE CARRIAGE The structure is composed of a carriage, where the internal grinding spindle is located. The working feed, is obtained by a re-circulating ball screw and preloaded nut. The screw movement is assured by a brushless motor. The incremental optic rule guarantees a wheelhead positioning precision of 0,001 mm. INTERNAL GRINDING SPINDLE As there are many and various types of Internal Grinding Spindles, according to the diameters and lengths that need to be ground, the machine is supplied without an internal grinding spindle, so that the customer may select which type is more suitable for his job. The machine is manufactured standard with a belt transmission suitable for diam. mm. 60, diam. mm. 80 and diam. mm. 100 internal grinding spindles. On request, high frequency spindles may be assembled. WHEELHEAD FOR FACE GRINDING The structure is composed of a carriage, where the face grinding device is located. The positioning is obtained by an hydraulic cylinder. The diamond dressing device is assembled on the face grinding device casing. MANUAL FEED HANDWHEELS Electronic type, with double selection of the increments division 0.1 - 0.01 and 0.001 mm. for wheelhead and table movements. DIAMOND DRESSER The internal diamond dressing device is very strong and is positioned on the table. It starts hydraulically, when the dressing operation is selected, by the operator. The dressing operation may be carried out manually or in automatic cycle. EQUIPMENT AND ELECTRICAL PLANT In a cooled cabinet, separate from the machine. HYDRAULIC PLANT The hydraulic power pack, is separate from the machine and activates the hydraulic diamond dresser and face grinding device. LUBRICATION PLANT The lubrication power pack, is separate from the machine and supplies continuous oil to the wheelhead guides. The recovered oil is filtered and then resent to the power pack. The re-circulating ball screw nut for the working feed, is grease lubricated. COOLANT PLANT Large capacity tank for the coolant water, complete with electric equipment. Equipped with coolant magnet cleaner and coolant paper roll cleaner. PROTECTIONS For the protection of the operator all movable parts are covered with suitable guards. Precisely: protection casing for belts, protection casing for grinding wheel and bellows for guides. The machine is completely closed and the front protection is a sheet sliding doors with poly-carbonate shields. A safety device, does not permit the automatic cycle to start if the front sliding doors are open.

Datasheet

Request / Contact

.1124-93850-20191213155810240199.jpg)

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-93850 · Internal and Face Grinding Machine

KRAFT (Etech) - KGI-150 - - Fabrikneu -

Technical details

Datasheet

Request / Contact

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-93805 · Internal and Face Grinding Machine

Robbi - IGR 250 - - Fabrikneu - Siemens 840 D oder SPS von Sie

Technical details

PERFORMANCE AND PRECISION DEGREE Robbi grinding machines are according to the international precision normes ISO 2433. The table movement linearity is guaranteed by a max. deviation of 0,002 mm/mt. The obtainable grinding roundness is : 0,4m (**) (**) for a test workpiece ground in our factory during machine testing The CNC controls : Wheel head movement (AXIS X) Longitudinal table movement (AXIS Z) Work head spindle rotation speed The available programs permit the programming of the following grinding cycles Plunge Cylindrical pass Cylindrical pass with interpolation between table and wheel movement to grind taper workpieces Radius The software for the workpiece grinding operation is very simple and intuitive. To facilitate the programming the software is equipped with an exemplifying graphics, to input the data for each parameter. The software, has been specially studied, so as to permit also non specialised operators to programme without any problems complex workpieces. When the workpiece grinding programme has been completed the CNC will automatically make up a summary list, where only the geometric parameters are evidenced. This list permits with a glance to verify the complete programme; this operation is very helpful to verify eventual input data errors or to check rapidly a workpiece programme when reloaded from the file. While the programme is in execution, it is possible to intervene and modify in real time the technologic parameters, such as: increments, dwell inversion times, sparkout passes. Also, it is possible to intervene with the jog handwheel. The Grinding Machine is composed of : BASE Structure in normalised and stabilised cast iron with large ground guides. The lubrication plant supplies a constant oil flow distributed over the complete length of the guides. In the middle of the base, there is positioned the ball screw for the table longitudinal movement. On all the lower part of the perimeter are situated the recesses for machine levelling. Considering the base structure, usually a foundation is not required. TABLE The table is manufactured in two parts, both are in normalised and stabilised cast iron. The lower part is composed of wide guides which are ground and accurately hand scrapped, for a better sliding. The upper part, is swivelable in the two directions, suitable for grinding tapered workpieces. It includes a micrometric device with centesimal dial gauge for taper control. WORKHEAD The structure in normalised, stabilised and well ribbed cast iron, allows to support the workpiece weight and the force generated by the grinding operation. The spindle rotates on high precision ball bearings, guaranteeing restricted tolerance and maximum rigidity in the working. The spindle rotation is by means of a three phase motor with variable speed controlled by an inverter. INTERNAL GRINDING SPINDLE CARRIAGE The structure is composed of a carriage, where the internal grinding spindle is located. The working feed, is obtained by a re-circulating ball screw and preloaded nut. The screw movement is assured by a brushless motor. The incremental optic rule guarantees a wheelhead positioning precision of 0,001 mm. INTERNAL GRINDING SPINDLE As there are many and various types of Internal Grinding Spindles, according to the diameters and lengths that need to be ground, the machine is supplied without an internal grinding spindle, so that the customer may select which type is more suitable for his job. The machine is manufactured standard with a belt transmission suitable for diam. mm. 60, diam. mm. 80 and diam. mm. 100 internal grinding spindles. On request, high frequency spindles may be assembled. WHEELHEAD FOR FACE GRINDING The structure is composed of a carriage, where the face grinding device is located. The positioning is obtained by an hydraulic cylinder. The diamond dressing device is assembled on the face grinding device casing. MANUAL FEED HANDWHEELS Electronic type, with double selection of the increments division 0.1 - 0.01 and 0.001 mm. for wheelhead and table movements. DIAMOND DRESSER The internal diamond dressing device is very strong and is positioned on the table. It starts hydraulically, when the dressing operation is selected, by the operator. The dressing operation may be carried out manually or in automatic cycle. EQUIPMENT AND ELECTRICAL PLANT In a cooled cabinet, separate from the machine. HYDRAULIC PLANT The hydraulic power pack, is separate from the machine and activates the hydraulic diamond dresser and face grinding device. LUBRICATION PLANT The lubrication power pack, is separate from the machine and supplies continuous oil to the wheelhead guides. The recovered oil is filtered and then resent to the power pack. The re-circulating ball screw nut for the working feed, is grease lubricated. COOLANT PLANT Large capacity tank for the coolant water, complete with electric equipment. Equipped with coolant magnet cleaner and coolant paper roll cleaner. PROTECTIONS For the protection of the operator all movable parts are covered with suitable guards. Precisely: protection casing for belts, protection casing for grinding wheel and bellows for guides. The machine is completely closed and the front protection is a sheet sliding doors with poly-carbonate shields. A safety device, does not permit the automatic cycle to start if the front sliding doors are open.

Datasheet

Request / Contact

- GWM GmbH

- Gewerbestr. 2

- 79639 Grenzach-Wyhlen

- Deutschland

-

(0049) 7624 9082 0

07624 9082-206 -

info@gromag.ch

www.gromag.ch

#1044-3252 · Internal and Face Grinding Machine

VOUMARD - 202 - - 1977 -

Technical details

Accessories : Three-jaw chuck 125 mm tool spindle head swivelling 30 - 0 - 90 degrees 2 grinding spindles Spare belt unfortunately no coolant tank

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-0501202 · Internal and Face Grinding Machine

WMW GLAUCHAU - SIP 200-315/1 - - 1969 -

Technical details

Datasheet

Request / Contact

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-SL241 · Internal and Face Grinding Machine

Naxos Union - - - -

Technical details

Surface Grinding Machine - Horizontal

- Hans Klein Werkzeugmaschinenhandel GmbH

- Im Mühlgut 2-4

- 77815 Bühl

- Deutschland

-

0049 (0) 7223 9617-0

0049 (0) 7223 58512 -

info@klein-werkzeugmaschinen.de

www.klein-werkzeugmaschinen.de

#1052-10020 · Surface Grinding Machine - Horizontal

MAEGERLE - F 10 - - unbekannt -

Technical details

Accessories: magnetic plate 680 x 200 mm, grinding wheel with flange (ø 240 x 25 mm), wet grinding attachment

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2252 · Surface Grinding Machine - Horizontal

ABA / ZIERSCH & BALTRUSCH - ECOLINE 1206 A - - 2008 - SIEMENS LC 200 / TP277

Technical details

CNC precision, surface and profile grinding machine CNC control SIEMENS LC 200 / TP277 Table load maximum to the magnetic chuck 1200 kg Drives: X-axis drive hydraulic Y and Z-axis drive with servo drive and ball screw measuring system: X-axis rotary with rotary encoder Y and Z axis linear scale traverse paths X axis 1400mm Y axis 600mm Z axis 600mm Grinding length 1250 mm Grinding width 600 Distance between table and spindle center 700 mm Grinding wheel diameter 400 mm Grinding wheel width 100 mm Grinding wheel bore 127 mm

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9014 · Surface Grinding Machine - Horizontal

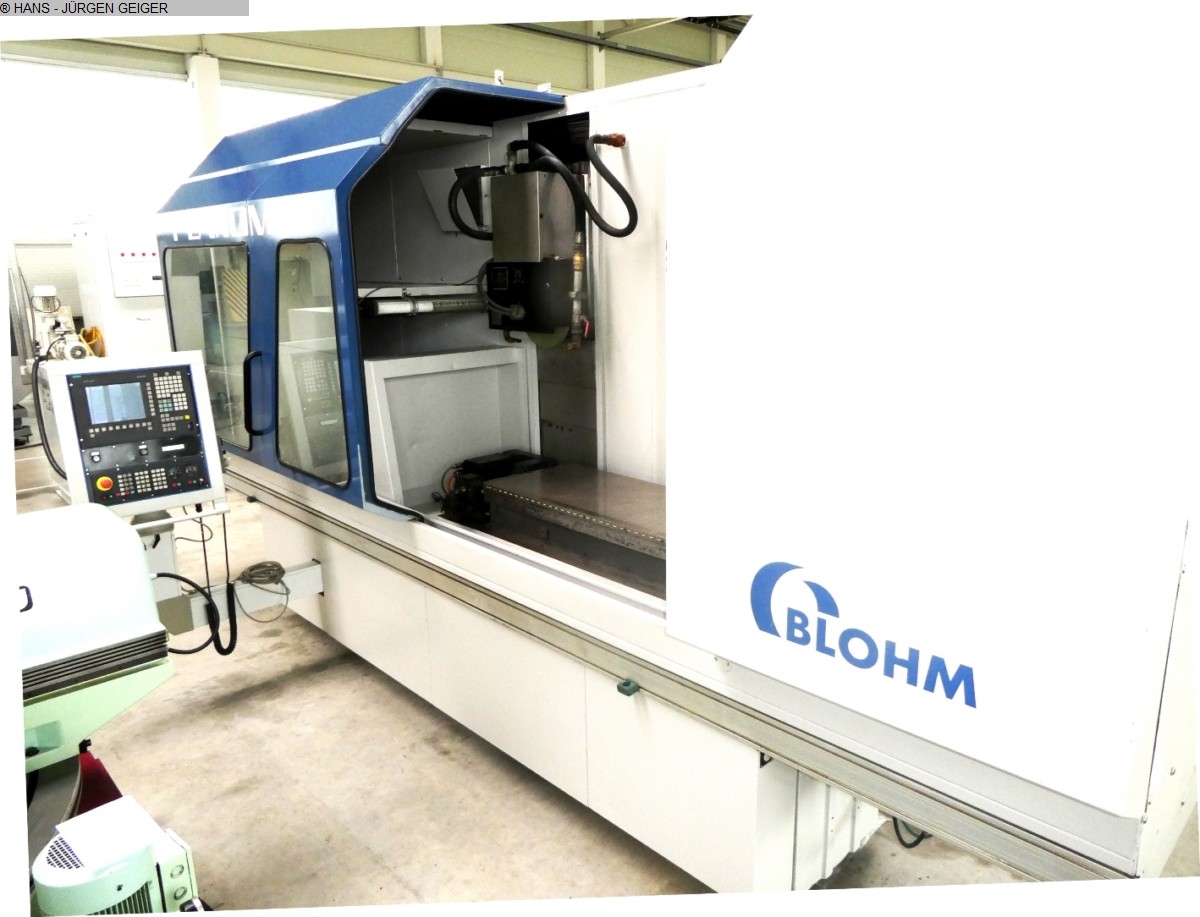

BLOHM - Planomat 612 - - 2006 - Ergomatic Blohm

Technical details

Surface Grinding Machine - Horizontal BLOHM - Planomat 612

- Gustav Schönberger GmbH

- Hünderstr. 14

- 74080 Heilbronn

- Deutschland

-

(0049)7131 46060

(0049)7131 460620 -

schoenberger@gsh-maschinen.de

www.gsh-maschinen.de

#1036-061692 · Surface Grinding Machine - Horizontal

ELB - Perfekt 15 SPS - - 2005 -

Technical details

- automatic infeed - electro magnet - coolant device Technische Daten / technical details: Schleiflänge / grinding length 1500 mm Schleifbreite / grinding width 600 mm Werkstückhöhe / workpiece height 400 mm Längsachse X / longitudinal travel X 1600 mm Querachse Z / cross travel Z 560 mm Vertikalachse Y / vertical travel Y 400 mm Elektromagnetabmessungen / electro magnet dimensions 1500x600 mm Schleifscheibe / grinding wheel 400x100x127 mm Antriebsleistung Schleifspindel / drive capacity grinding spindle 10 kW Gewicht der Maschine ca. / weight ca. 7100 kg Technische Daten, Zubehör und Beschreibung der Maschine sind unverbindlich - Technical data, accessories and description of the machine are not binding.

- Marcels Maschinen AG

- Anthoptstrasse 11

- 8222 Beringen (Schaffhausen)

- Schweiz

-

(0041) 44 872 3400

(0041) 44 872 3403 -

info@marcels-maschinen.ch

http://www.marcels-maschinen.ch

#1065-4675 · Surface Grinding Machine - Horizontal

ABA / ZIERSCH & BALTRUSCH - Starline 600E NC-SP - - 2004 -

Technical details

SURFACE % PROFILE GRINDING MACHINE magnetic plate 600x300mm Dresser on table Exhausting device More details on www.marcels-maschinen.ch

Datasheet

Request / Contact

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-1599 · Surface Grinding Machine - Horizontal

ABA - Powerline - - 2001-2023 - SINUMERK 840 D

Technical details

Equipment and accessories - Linear measuring systems in Y- and Z-axis - All linear axes with digital servo motors and ball screw drive - Belt filter system with paper belt filter, tank capacity 640 l, coolant pump 200 l/min/4 bar - Manual coolant nozzles - adjustable - Automatic working chamber door pneumatically controlled - Electro-permanent magnetic plate 800 x 500 mm, pendulum pole pitch 18 mm - Automatic grinding wheel balancing device Fa. MPM - Full enclosure of the working area in stainless steel partial execution with LED working area lighting - Manually operated door, safety interlock in automatic mode - Portable electronic handwheel in automatic and manual mode for all axes - Three-color signal light - Electrical equipment 400V/50Hz - Switch cabinet cooling unit - Machine feet - Painting RAL 9002 (grey white), RAL 5010 (gentian blue) - Rinsing gun with hose and holder in the operating area - Approx. 5 pcs. grinding wheel flanges *** Machine prepared for grinding mist suction *** Grinding programs - Surface grinding - Plunge grinding - Profile grinding - Automatic program sequence with roughing, finishing, fine finishing and burnout - Multiple plunge-cut grinding for economical production - Surface grinding with continuous, infinitely programmable cross feed - Calibration of the grinding wheel (calibrate, backfeed, round corners) - Face grinding with back pull dressing - Dressing in grinding cycle with lift-off amount - Fully automatic compensation of dressing amounts - Tool management Dressing Technology Table dresser -straight- TAG: Dresser fixed on the machine table, roughing and finishing station with dressing tiles are arranged one behind the other, cylindrical dressing of grinding wheels for surface and plunge grinding, suitable for corundum and silicon carbide grinding wheels, cycle software with input menu Pre-profiler VPG-150: incl. diamond roughing wheel width 1.5 mm For economical pre-profiling (roughing out) of the grinding wheel, profiling unit firmly mounted on the table, suitable for corundum and silicon carbide grinding wheels, CNC dressing cycle for pre-profiling Table profile dresser TAD: Suitable for diamond wheel DFR, D = 120, tip radius r = 0.1 - 1mm, flank angle 28°,40°, 60°. Profile depth max. 20 mm, contour accuracy +/- 0.0025 mm, swivel angle +/- 70°, profiling in the program by means of graphical operator guidance in 3-D interpolation

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08117 · Surface Grinding Machine - Horizontal

DANOBAT - PSG - 1000 - - 2001 - Fanuc 210i - M

Technical details

CNC surface grinding machine Clamping area of the table 1000 x 500 mm Clamping surface for magnetic particle board 1000 x 500 mm Largest grinding surface: L x W x H 1000 x 600 x 450 mm Largest distance from table to spindle center 650 mm Table speed in the longitudinal direction 1 - 30 m / min Max. Table load 1500 kg Grinding wheel: diameter x width x bore 400 x 50 x Ø 127 mm Grinding spindle drive 7.5 kW Spindle speed 1500 rpm Connected load 20 kW Space required L x W x H 3950 x 3150 x 2550 mm Weight 5500 kg Equipment CNC control Fanuc 210i - M Electro magnetic plate 1000 x 500 mm Coolant device with paper filter Several Grinding wheels with flanges Digital display Condition machine is in good condition

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9054 · Surface Grinding Machine - Horizontal

ZIERSCH & BALTRUSCH - Starline 500 E - - 2001 - Simatic OP 27 Siemens

Technical details

Surface Grinding Machine Horizontal Ziersch & Baltrusch - Starline 500 E - approx. 9.340 spindle hours - 4x NEW grinding wheels - 4x flanges - LTA suction with stand - Splash guard for work area (half height) - protective door - Infinitely variable speed control of the grinding spindle - Heidenhain: Incremental measuring system, incremental encoders, proximity switches

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-18001 · Surface Grinding Machine - Horizontal

ZIERSCH & BALTRUSCH - FMNC SUPERPLUS ZB84 - - 2000 - Simatic OP27

Technical details

Grinding spindle KESSLER Clamping magnet SAV 800x400 mm Balancing unit MPM Coolant system with band filter DGS SBF 60 8 Grinding wheel flanges

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2254 · Surface Grinding Machine - Horizontal

ROSA - LINEA STEEL 13.7 - - 2000 - E.C.S. CNC 2401

Technical details

CNC surface grinding machine in very good condition The machine can be demonstrated under power Equipment: - CNC control E.C.S. CNC 2401 System III - Magnetic plate 1400 x 500 mm - Coolant device with paper band filter Accesories: Machine shoes / fixators Machine documentation Various new spare parts, including coolant pump, grinding wheel with flange, guideway covers, electronics assembly, etc.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-775469 · Surface Grinding Machine - Horizontal

GEIBEL&HOTZ - FS 1050 GT CNC Rh - - 2000 -

Technical details

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-769774 · Surface Grinding Machine - Horizontal

BLOHM - PLANOMAT 616 - - 2000 -

Technical details

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03150 · Surface Grinding Machine - Horizontal

CHEVALIER - FSG- 1632 - - 1998 -

Technical details

automatic vertical feed, dressing devise, electro magnet,800 X 400 coolant with paperfilter, hydraulic separate

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-775880 · Surface Grinding Machine - Horizontal

GEIBEL & HOTZ - FS 850 GT SL - - 1998 -

Technical details

- Kirchgeorg Werkzeugmaschinen

- Frankfurter Straße 141

- 63303 Dreieich-Sprendlingen

- Deutschland

-

0049-(0)-6103-9909-0

0049-(0)-6103-9909-50 -

info@kirchgeorg.de

www.kirchgeorg.de

#1072-20447 · Surface Grinding Machine - Horizontal

JUNG - JUTEC 420 - - 1997 -

Technical details

- Serial-No.: 9821097 - automat. vertical feed - electr. handwheel - digital display 2 axes HEIDENHAIN - head dresser with compensation - coolant device - magnetic separator

Datasheet

Request / Contact

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-04763 · Surface Grinding Machine - Horizontal

FAVRETTO - MA75 - - 1996 -

Technical details

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Please note: The machine is dismantled and ready for loading. It is not possible to show it under power or make a video. Our offer includes already the best pictures. So we don’t have and won’t send additional pictures. ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-770719 · Surface Grinding Machine - Horizontal

GEIBEL & HOTZ - FS 1050 GT CNC - - 1996 -

Technical details

TOP Manufacturer:

ROBBI - JOTES - NAXOS UNION - VOUMARD - KRAFT (ETECH) - WMW GLAUCHAU -