Gear Hobbing Machine - Horizontal

Machinelist: Gear Hobbing Machine - Horizontal

Gear Hobbing Machine - Horizontal

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-19056 · Gear Hobbing Machine - Horizontal

BARBER COLMAN - 16 - 16 - - ca. 1980 -

Technical details

Datasheet

Request / Contact

- STEINHAND GmbH

- Am Stahlwerk 15

- 45527 Hattingen

- Deutschland

-

+49 (0) 2324 / 977 26 - 01

+49 (0) 2324 / 977 26 - 99 -

info@steinhand.de

www.steinhand.de

#2026-1643 · Gear Hobbing Machine - Horizontal

GLEASON-PFAUTER - P90 - - 2015 - Siemens - Sinumerik 840 D

Technical details

Gear Hobbing Machine - Horizontal | GLEASON-PFAUTER - P90 equipped with magnetic chip conveyor for dry and/or wet machining. Furnishing: - attached extraction system: Ringler, - with platform, - subindulgence, - subsequent loading and unloading handling: Epson - LS6-602S (built 2018), - sorting unit, - Calibration unit: Stotz, control: Siemens - HMI, - Work cell: Eagle - AMZ, with workpiece tray, - position check, - exit conveyor belt, - Control cabinet, with cooling unit: Rittal - Workspace, - tailstock, - measuring device, - refrigeration system, - Industrial robots: Epson, - goods carrier, - conveyor belts, - control panel, The machine is in very good condition. For additional equipment information please refer to the original order confirmation which is included in the offer of this machine. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - #Tags: P 90 | P-90 | Gleason Pfauter P90

- STEINHAND GmbH

- Am Stahlwerk 15

- 45527 Hattingen

- Deutschland

-

+49 (0) 2324 / 977 26 - 01

+49 (0) 2324 / 977 26 - 99 -

info@steinhand.de

www.steinhand.de

#2026-1640 · Gear Hobbing Machine - Horizontal

GLEASON-PFAUTER - P60 - - 2014 - Siemens - Sinumerik 840 D

Technical details

Gear Hobbing Machine - Horizontal | GLEASON-PFAUTER - P60 equipped with magnetic chip conveyor for dry and/or wet machining. Furnishing: - attached exhaust system for dry processing: Ringler, - Noise insulation for dry milling machine - with platform, - subindulgence, - subsequent loading and unloading handling: Epson - LS6-602S (built 2018), - sorting unit, - Calibration unit: Stotz, control: Siemens - HMI, - Work cell: Eagle AMZ, with workpiece tray, - position check, - exit conveyor belt, - Control cabinet, with cooling unit: Rittal - coolant device, - Automation unit: AMZ, The machine is in very good condition. For additional equipment information please refer to the original order confirmation which is included in the offer of this machine. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - #Tags: P 60 | P-60 | Gleason Pfauter P60

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E23022 · Gear Hobbing Machine - Horizontal

GLEASON- PFAUTER - P 60 - - 2002 -

Technical details

- IVW GMBH

- Niederrheinstr.298

- 40489 Düsseldorf

- Deutschland

-

(0049)211-4184428

(0049)211-4184430 -

cd@ivwgmbh.com

www.ivwgmbh.com

#1088-E00864 · Gear Hobbing Machine - Horizontal

PFAUTER - P100 - - 1999 - Siemens 840 C

Technical details

- IVW GMBH

- Niederrheinstr.298

- 40489 Düsseldorf

- Deutschland

-

(0049)211-4184428

(0049)211-4184430 -

cd@ivwgmbh.com

www.ivwgmbh.com

#1088-E00863 · Gear Hobbing Machine - Horizontal

PFAUTER - P100 - - 1998 - Siemens 840 C

Technical details

- IVW GMBH

- Niederrheinstr.298

- 40489 Düsseldorf

- Deutschland

-

(0049)211-4184428

(0049)211-4184430 -

cd@ivwgmbh.com

www.ivwgmbh.com

#1088-E00862 · Gear Hobbing Machine - Horizontal

PFAUTER - P100 - - 1997 - Siemens 840 C

Technical details

- IVW GMBH

- Niederrheinstr.298

- 40489 Düsseldorf

- Deutschland

-

(0049)211-4184428

(0049)211-4184430 -

cd@ivwgmbh.com

www.ivwgmbh.com

#1088-E00861 · Gear Hobbing Machine - Horizontal

PFAUTER - P100 - - 1995 - Siemens 840 C

Technical details

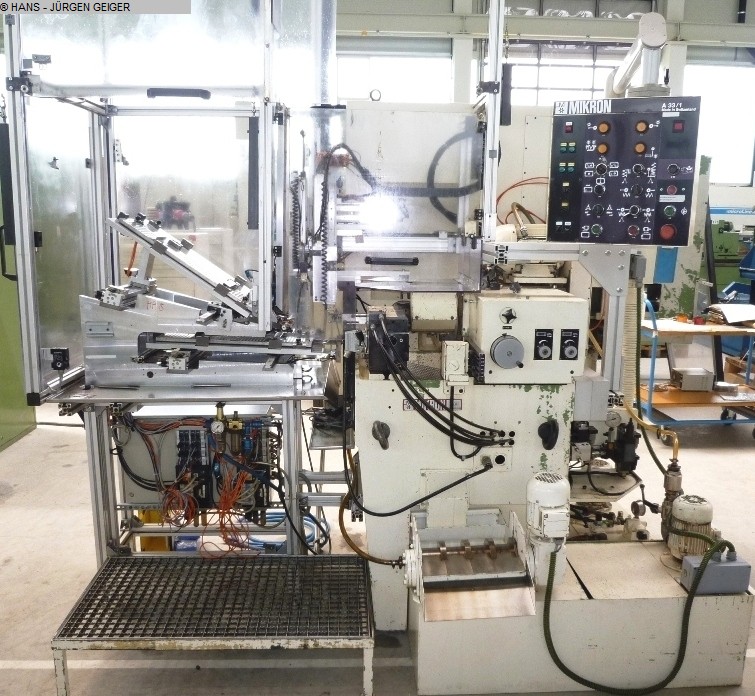

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-473370a · Gear Hobbing Machine - Horizontal

MIKRON - A 35/36 CNC - - 1992 -

Technical details

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E23084 · Gear Hobbing Machine - Horizontal

PFAUTER - PE 125 H - - 1992 - Bosch CC 220

Technical details

Machine in very nice condition! More machines under www.emuk.info

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24159 · Gear Hobbing Machine - Horizontal

MIKRON - A 35 - - 1991 -

Technical details

Datasheet

Request / Contact

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03822 · Gear Hobbing Machine - Horizontal

LIEBHERR - LC255 - - 1987 - Siemens

Technical details

- Isabelle Knops

- Opladener Str. 126

- 40789 Monheim am Rhein

- Deutschland

-

+49 (0)2173-4999611

+49 (0)2173-8546560 -

isabelle.knops@isabelleknops.com

www.isabelleknops.com

#2013-E0450 · Gear Hobbing Machine - Horizontal

PFAUTER/RICHARDON - P 253 CNC - - 1985/2002 - SINUMERIK 840 C

Technical details

5-axis gear hobbing machine / Brand: PFAUTER / Type: P 253 CNC Original year of construction: 1985, Modernization: 2002 (RICHARDON GmbH) The retrofit in 2002 to a 5-axis control system - SINUMERIK 840 C - was carried out by RICHARDON GmbH and included: Modification of the drive kinematics, i.e. partial and differential change gears have been removed. The axles were fitted with digital drives. Most of the mechanics were removed. The milling head was given a tangentil axis. The machine can be inspected by appointment under power. Condition: ready for immediate use. TECHNICAL DATA: Working area: - Max. Module in steel with approx. 600 N/mm² tensile strength: 6 mm - Straight gears: * Max. Tool diameter: 250 mm * Max. Axial slide travel: 250 mm - Min. Number of workpiece teeth: 4 Workspace dimensions: - Diameter of the workpiece table: 250 mm - Diameter of the table bore: 63 mm - Diameter of the workpiece mandrel: 30 mm - Max. Gear hobber: * Diameter: 130 mm * Length: 160 mm - Diameter of the milling arbours: 22, 27, 32, 40 mm - Centre distance between milling cutter and workpiece: * Min. Distance: 10 mm * Max. Distance: 210 mm - Mounting cone for cutter arbours: 4 Morse taper - Max. Milling cutter displacement: 115 mm Speeds and feeds: - Milling cutter speeds: * Five-stage V-belt pulley, adjustable in stages: 125 - 400 rpm * DC main drive: 100 - 400 rpm - Axial feed: 0,63 - 6,30 mm/WU - Radial feed: 0,25 - 2,50 mm/WU - Tangential feed: 0,20 - 2,00 mm/WU Electrical equipment: - Operating voltage: 400 V three-phase - Control voltage: 230 V alternating current - Magnet voltage: 24 V direct current - Frequency: 50 Hz - Connected load of the machine: approx. 40 kVA Electrical cabinet with integrated cooler for temperature control. Weight and space requirements: - Machine weight: approx 3.500 kg - Length/Width/Height: 3,74 x 2,6 x 2,6 m There is no guarantee for correctness and completeness of the technical details and accessories. - Subject to prior sale -

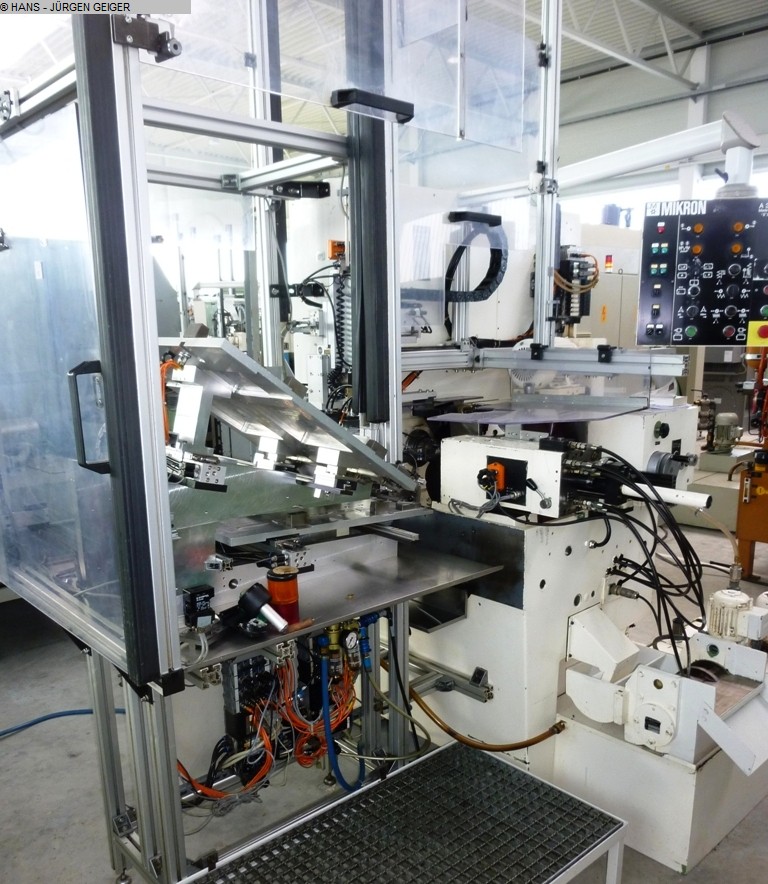

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-448351 · Gear Hobbing Machine - Horizontal

MIKRON - A 33/1 - - 1985 -

Technical details

M I K R O N (Switzerland) Fully Automatic Gear Hobber for Worm Gears Model A 33 / 1 Year 1985 Ser.-No. 14.06/14.07/14.15 ____________________________________________________________ max. gear- without feed magazine approx. 80 mm max. gear- with feed magazine approx. 50 mm Module max. 2, / 2,5 Axial milling length approx. 150 mm max. workpiece-mounting length approx. 200 mm Milling slide can be swivelled up to 90 degrees Milling cutter - 24 - 50/63 mm Max. radial distance of milling slide 0-14/18 mm Milling cutter adjustment max. 25 mm Milling cutter speed 212 - 2.000 rpm Axial feed range infinitely adjustable 0,05 - 4,0 mm/workpiece rotation radial infinitely adjustable 0,2 - 200 mm/min. Milling spindle drive 3 kW Total electrical load approx. 10 kW - 50 Hz - 380 Volt Weight approx. 2.400 kg Accessories/Special Features: " Fully automatic operation cycle and minimum idle times due to programmable SIEMENS Program Controls S 5 for all machining steps i.e. rapid gear, feed, milling cutter on/off for the loading device, tailstock, possibly shifting, etc. with unit counter, program numbering including 30 different numeric error displays Pneumatic workpiece-loading and unloading facility parallel to work piece axis upright for rod workpieces approx. 140 mm long x 8 mm , including pneumatic double gripper for loading and unloading of work pieces. Raw parts are inserted into change cassettes externally and then placed into the loading device. The double gripper places the parts between workpiece spindle and tailstock, the tailstock spindle sleeve pushes the parts in the main spindle collet and clamps them simultaneously. The finished parts are ejected from the main spindle, then placed back again into the finished parts cassette by the gripper. The whole process is electrically monitored and checked. The complete loading facility is encased by plexiglass. " Hydraulic work piece clamping device including collets and hydraulic ejector " separate cooling system with magnetic separator * separate hydraulic system * various change gears This machine is set up for worm gears/armature shafts that can be used for adjustable car seats, window lifters, etc.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-482607 · Gear Hobbing Machine - Horizontal

MIKRON - A 33/0 - - 1982 -

Technical details

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23254 · Gear Hobbing Machine - Horizontal

WMW-Modul - ZFWZ 250 x 5A - - 1975 -

Technical details

Additional information: Application: Gear hobbing machine for gear cutting of spur and helical gears, worm gears and rollable profiles Cycle milling and single milling as well as up-cut and climb milling Specifications for machining spur and worm gears: -Outer Ø max. 250mm with counterholder -pitch max. 5mm -Tooth helix max. 45° -Tooth width max. axial milling 200mm and radial-axial milling 240mm -Milling width max. clamping table counterholder 655mm Milling slide: -swivelling 210° -travelling distance 350mm -feed, 2 directions, 16 steps in the range 0.2 - 6.3 mm/revolution Further features: -counter-point taper MK4, co-rotating -Centre distance of milling/clamping spindle with counter-holder min./max.: 30 / 240 mm -Counterholder with guide bushes (clamping arbor and milling arbor)

Datasheet

Request / Contact

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-E23086 · Gear Hobbing Machine - Horizontal

KOEPFER - 172 - - 1972 -

Technical details

- Kurt Steiger Werkzeugmaschinen GmbH

- Flachstr. 11

- 65197 Wiesbaden

- Deutschland

-

+49 (0) 611/421047

+49 (0) 611/421040 -

info@kurt-steiger.de

www.kurt-steiger.de

#2043-26365B · Gear Hobbing Machine - Horizontal

KOEPFER - 135 - - 1968 -

Technical details

Gr. to fraesender Ø 24 mm milling cutter diameter: 70 mm

Gr. to fraesender Ø 50 mm milling cutter diameter: 46 mm

Gr. to fraesender Ø Magazine: 40 mm

Gr. Milling length minus gate: 75 mm

Gr. Workpiece length with magazine: 75 mm

Gr. Depth: 4 mm

Gr. Module: 1.25

KL. being milled tooth number: 3

Main spindle hole: 18 mm

Clamping Collet clamping area: 3-18 mm

I9cyejl

9 cutter speed: 222-1410 RPM

10 longitudinal feeds: 0.031-1.25 mm

Electr. Supply: 380 V, 1 kW

Weight: 850 kg

Space requirements: 1050 x 700 x 1500 mm

Datasheet

Request / Contact

- Emuk Maschinenhandel GmbH

- Siemensstrasse 24

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 943161

-

info@emuk.info

www.emuk.info

#2070-24039 · Gear Hobbing Machine - Horizontal

KOEPFER - 170 - - -

Technical details

Gear Shaping Machine

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24154 · Gear Shaping Machine

LORENZ - SN 4 - - ca 1981 -

Technical details

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-23230 · Gear Shaping Machine

LORENZ - SN 4 - - ca 1981 -

Technical details

Datasheet

Request / Contact

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-E23259 · Gear Shaping Machine

GLEASON- PFAUTER - P 1200 S - - 2008 - Siemens 840D Powerline

Technical details

Gleason-PFAUTER CNC gear shaping machine P 1200 S for the production of internally and externally cylindrical gears with internal and external teeth and other rolling profiles and moulds profiles and moulds that regularly occur on the cylindrical workpiece circumference and for the production of profiles in the single part process. Special version with hydraulic shaping head H1 SCOPE OF EQUIPMENT: - Basic machine P1200S, Siemens 840D Powerline (XP) - Hydraulic shaping head H1 - Signal light (3-colour) - Extended software for fault diagnosis - Telephone diagnosis system - Chip disposal through table bore - Set of adjusting wedges - Monitoring devices - Warm-up programme - Network connection (Ethernet) - 19" flat control panel OP 015A - Offline version "dialogue programming - Vapour separator make "3nine" type KLARA - Machine installation under floor - Rinsing gun - Mounting device - Cutting wheel holder ( 3 pieces ) - Cutting wheel holder for sheep cutting wheels - Cutting wheel holder for sheep cutting wheels - Special cutting wheel holder - Preparation for retrofitting paper belt filter system - Measuring device for machine P 1200 S - Clamping base body - BDE/MDE interface in the machine control cabinet Modification of vapour separator make "3nine" type Klara type EMMA Working range and technical data: Nominal workpiece diameter External toothing. . . . . . . . 1.200 mm Internal gearing. . . . . . . . 1.200 mm Largest workpiece circulation Ø without counter stand... 1.400 mm Nominal machine module approx. - with hydraulic impact head H1... 16 mm Shaping spindle stroke rate range - with hydraulic shaping head H1 max. 80 min-1 Largest toothing width - with hydraulic shaping head H1... 350 mm Smallest pitch height of the hydrostatic screw guide - with hydraulic shaping head H1... 850 mm Smallest/largest distance between tool and workpiece axis - with hydraulic shaping head H1... 0 - 750 mm Axial slide adjustment range - with hydraulic shaping head H1... 1.100 mm Lowest shaping spindle position above table with hydraulic shaping head H1 ** with upper position Shaping stroke... 560 mm Column side offset range - with hydraulic pusher head H1... +/- 50 mm Mould mounting cone - with hydraulic shaping head H1 - HSK-80(hollow shank taper according to DIN 69063) Workpiece with external gearing: - Module max. 16 mm, - max. toothing width 350 mm, - max. external Ø 1.200 mm, Workpiece with internal gearing: - Module max. 16 mm, - max. toothing width 350 mm, - max. circulation Ø 1.400 mm, - max. internal Ø 1.200 mm, - max. shaping wheel Ø 260 mm, - Mounting in shaping spindle HSK-80, - Slide travel; X/Y/Z- 750 /100 / 1.100 mm, Workpiece table: - Outer Ø 1.200 mm, - bore 300 mm, - max. load 150 kN, - Cooling unit, Küma, type OWT600-3KK, year 2008, - Hydraulic unit, manufactured by Parka, - Centrifuge, made by Steimel, - Air filter, Indusa, type EL4001NTDASECL/O, version AOO, max. air capacity 4.000 m³/h

Datasheet

Request / Contact

- Leyendecker & Hollmann GmbH

- Giesenheide 18

- 40724 Hilden

- Deutschland

-

+49 (2103) 28097-0

+49 (2103) 28097-99 -

info@LHmachine.com

www.LHmachine.com

#1083-03265 · Gear Shaping Machine

GLEASON- PFAUTER - P 1200 S - - 2008 - Sinumerik 840 D

Technical details

Workpiece with external gearing Largest modulus (in steel with approx. 600N/mm²) 16 mm - Maximum gear width 350 mm - Largest outside diameter 1. 200 mm Workpiece with internal gearing Largest modulu (in steel with approx. 600N/mm²) 16 mm - Maximum gear width 350 mm - Maximum swing diameter 1. 400 mm - Maximum inner diameter 1. 200 mm Tool - Maximum impeller diameter 260 mm - Stroke length 50 mm – 380 mm Equipment/Accessoires: Special version with hydraulic cutting head H1 workpiece diameter: External gears 1. 200 mm Internal gears 1. 200 mm Largest workpiece swing diameter - without steady rest 1. 400 mm Oil mist exhauster „3nine“ type KLARA Cutting wheel holder (3 pieces) Measuring device for machine P 1. 200 S

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24003 · Gear Shaping Machine

GLEASON-Pfauter - GP 130 S - - 2005 - Siemens 840 D

Technical details

Counterhold without center hydraulically operated counter arm and Linear guides. For automatic ring loader, with 4 stations

Datasheet

Request / Contact

- 1

- 2

TOP Manufacturer:

PFAUTER - MIKRON - KOEPFER - GLEASON-PFAUTER - LIEBHERR - PFAUTER/RICHARDON - WMW-MODUL - BARBER COLMAN - GLEASON- PFAUTER -