Lathes

Machinelist: Lathes

Center Lathe

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

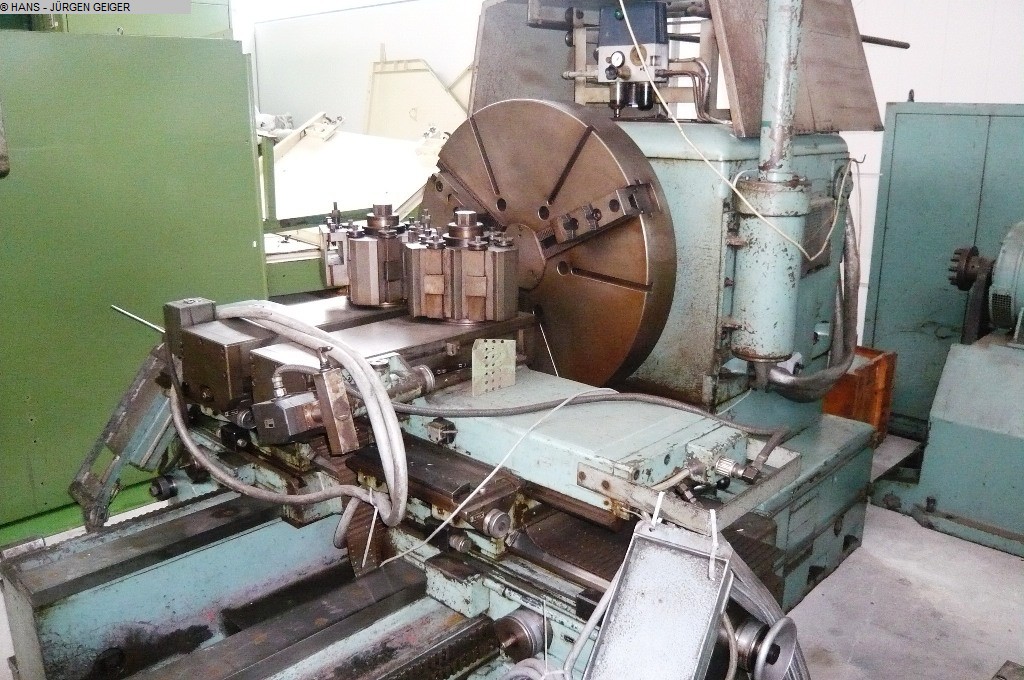

#1049-764908 · Center Lathe

VDF-BOEHRINGER - M 670 - - 1977 -

Technical details

Chucking Automatic Lathe-Single Spindle

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-453583 · Chucking Automatic Lathe-Single Spindle

INDEX - GS 30 - - 1990 -

Technical details

CNC Lathe

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-706038 · CNC Lathe

EMAG - VSC 250 DS - - 2004 - SIEMENS 840 D

Technical details

E M A G (Germany) Vertical CNC Controlled Hard Turning and Grinding machine with tool turret and workpiece handling System Model VSC 250 DS Year 2004 # M7 28.69324 _______________________________________________________ Turning Ø, max. 250 mm Turning length internal / external 100 mm Workpiece length min./max. 29 – 100 mm 6-positon tool turret Ø / swing-Ø 480/790 mm Workpiece spindle Slide travel, X / Z / stroke 680 / 400 / 200 mm Feed rate / Quick feed X/Z 45/30 m/min. Feed force X/Z 5,5/11 kN Spindle speed 4.300 / 6.000 rpm Spindle drive 28 kW Total electrical load, approx. 35 kW - 400 V - 50 Hz Weight, approx. 7,500 kg Accessories / Special Features: * CNC – Continuous Path Control SIEMENS Model 840 D, with colour monitor, graphics, menu-supervised dialogue programming, and all the usual options, cycles and subprograms, etc. * Hexagon Tool turret head with 6 tool positions (Ø 40 mm) without motorized tools posts, two positions T 3 u. T 6 equipped with grinding spindles with 42.000 rpm and with 18.000 rpm, using CBN discs resp. regular grinding tools * Workpiece handling device with WP transportation frames and circulation system and pick-up and unloading of finished parts directly through the motor spindle which is equipped with a hydraulic 3 jaws chuck make SMW Autobloc with membrane clamping and clamping control system. * MARPOSS MIDA Measuring Probe for measuring blank parts a. the finished parts * NORGREN air measuring system, hydraulic weight compensation of spindle, * Main elements of machine are temperature stabilized by a coolant system made by HYFRA * Recooler for the grinding coolant sitting on a large Coolant device consisting of SEITZ Paper Band filter and a mobile Chipconveyor, Magnetic separator, Centrallubrication, etc. Vertical CNC lathes offer a thermo-resistant construction (chips do not fall onto the machine bed),fast workpiece change times (pick-up system through the main spindle) and a ridged tool arrangement,which also allows unrelated machining work, like hard turning or grinding process on the same machine. Condition : Good. Machine can soon be inspected under power. Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-705010 · CNC Lathe

INDEX - G 200 - - 1998 - SIEMENS SINUMERIC 840 C

Technical details

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-766392 · CNC Lathe

INDEX - G 300 - - 1995 - SIEMENS SINUMERIC 840

Technical details

I N D E X (Germany) CNC Controlled Slant-Bed Chuck Lathe with Turret and Tailstock and INDEX CNC Control C 200 – 4 (SIEMENS) Model G 300 Year 1995 S/N 5000 65 _____________________________________________________________ Turning - Ø, with chuck, max. 300 mm Spindle bore 90 mm Max. Workpiece Swing dia. 400 / 590 mm Turning length / travel of turning slide, (X-Achse) max. 710 mm Turret head slide cross movement (Z-Axis) max. 140 mm Turret with 12 tool holder positions DIN 30 mm Feed range of turret slide / Quickfeed 0,1 - 20 m/Min. Feed Force of X/Z-Axis 8 – 13 kN Steplessly adjustable Spindle speeds up to 5.000 rpm Torque Forceon main spindle approx. 275 Nm Spindle drive 28 kW Total electrical load appr. 40 kW - 400 V - 50 Hz Weight 6,000 kg Accessories / Special Features: * INDEX CNC Control Model C 200-4 resp. SIEMENS 840 C for 3 Axes X/Z Axis and Main spindle as C-Axis (Spindle Orientation) Control Panel mounted swivable on front left side of machine. * Spindle orientation in 2,5° degree steps and Spindle indexing device * Mounted hydraulic 3 Jaws Chuck make FORKHARDT Model HS 250 with many Sets of jaws. Speed up to 5.000 rpm * INDEX- Turret with 12 positions for DIN 30 tool holders, prepared for driven tools and motorized by the indexing motor, Choice of approx. 40 pieces toolholders * Hydraulic Tailstock with stroke of 50 mm and with concentricity correction device * KNOLL – Swarf Conveyor with Coolant Device and High Pressure Pump, Sliding door, Oilskimmer, etc. Condition : Good to very good. Machine can be inspected under power. Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-279545 · CNC Lathe

INDEX - GSC 65 - - 1991 - C 200 / 8

Technical details

Swing Ø above bed, max. 300 mm Max. turning Ø for chucking work, approx. 250 mm Travel of Slides: Turret 1, X / Z travel 163 / 550 mm Turret 2, X / Z / Y travel 140 / 250 / 260 mm Spindle bore, approx. 65 mm Tool holder bore 30 mm Spindle speeds 25 - 5,000 rpm Feed range 0 - 15,000 rpm Spindle drive 0.5 - 40 kW Total electrical load 60 kW - 380 V - 50 Hz Weight, approx. 8,500 kg Accessories / Special Features * SIEMENS CNC Continuous Path Control, Model 880 (INDEX C 200-8) for at least 6 axes, with enlarged memory and with subprograms, simulation, etc. * Double column loading device for large workpieces, mounted above the machine. With 3-jaw gripper and storage system for blanks and finished parts, integrated in the CNC control. * Spindle indexing and positioning device, 7.5°. * Hydraulic high-power chuck (hollow clamping cylinder Ø 65 mm). Manufacturer: ROHM, Model HS 200/3-66, and ROHM Power Chuck, Model KFD HS 137 in the opposed spindle. * Driven tools in Turrets 1, 2 and 3, drive approx. 6 kW each. Tool stations: 8 / 12 / 8 + 28 tools in magazine = 55 tools altogether. * Tool measuring device for Turret 1. * Tool disk magazine for Revolver No. 2 with 28 tool positions and automatic tool changer. * Backwork is possible using the control unit for the 3rd turret. * Coolant device with large chip conveyor. * Automatic sliding doors. * Various other accessories. Price, ex stock EUR 49,000.-- Ideal machine for heavy and complex turned parts. Complete processing is possible, including backwork. Condition : Good to very good. Machine can be inspected under power. Delivery : Ex stock as inspected Payment : Net, after conclusion of contract Thank you for your interest. We have a selection of CNC lathes available. Please let us know your requirements

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-333531 · CNC Lathe

GILDEMEISTER - GAC 42 - - 1991 -

Technical details

CNC-lathe with bar feed with Sameca bar feed

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-346509 · CNC Lathe

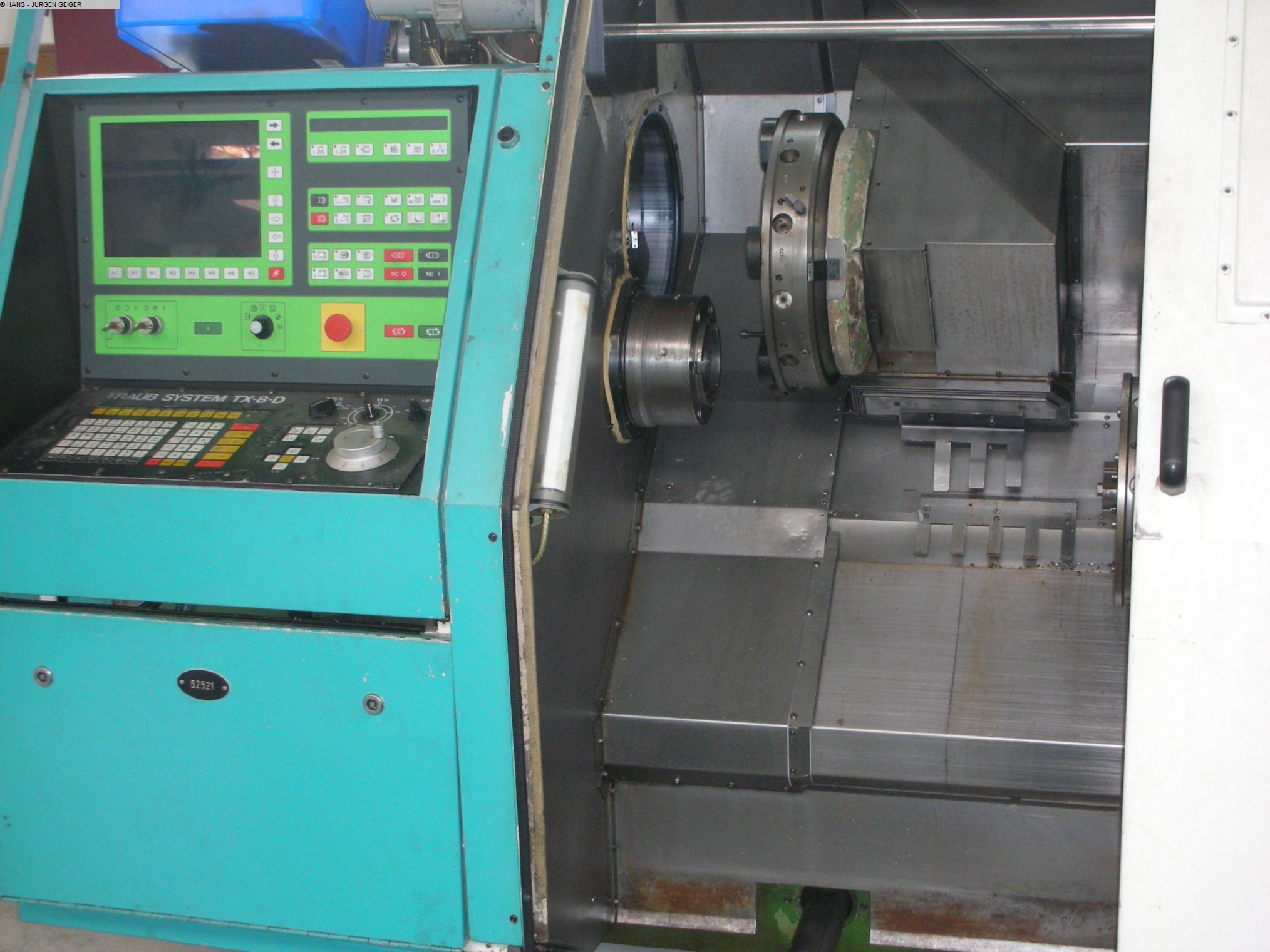

TRAUB - TNS 65/ 80 D - - 1990 - TX8D

Technical details

CNC Lathe with Bar Feed and 3 Turrets Very large spindle bore, with bar loading device Please ask for further details.

CNC-Vertical Turret Lathe - Single Col.

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-447347 · CNC-Vertical Turret Lathe - Single Col.

PITTLER - PV 1250 1-1 - - 1994 -

Technical details

P I T T L E R (Germany) CNC Controlled Vertical Turning and Milling Centre With Tool Changer and Pallet Changer Model PV 1250 / 1-1 Year 1994 _______________________________________________________ Turning Ø max. 1,000 mm Swing Ø max. 1,160 mm Turning length 800 mm X Axis - horizontal 1,300 mm Y Axis - vertical 800 mm Feed / quick feed 16,000 mm/min Main spindle speeds 10 - 1,000 rpm ! Main spindle speeds via separate C Axis 0.1 - 16 rpm Positioning accuracy of C Axis 360° + / - 5 " Tool holder ISO 50 Tool drive 22 kW Max. torque / spindle speed 315 Nm / 2,500 rpm Pallet size 630 x 630 mm Spindle drive 63 kW Total electrical load 97 kW - 400 V - 50 Hz Weight, approx. 25,000 kg Accessories / Special Features * CNC Contouring Control Model NUM 760 TX in 3 axes, with graphics, menu-guided dialogue programming, and all the usual options, cycles and sub-programs; with tool compensation, thread cutting cycles, constant speed programming, etc. * 2-axis CNC tool slide (1,300 x 800 mm) with driven tool holders, ISA 50 / 22 kW. * Tool changer with 16 tool holders, max. length 450 mm, max. weight 40 kg. * Pallet changing system, pallet size 630 x 630 mm, with setup station with indexing and drive of the pallet, and 2 separate pallet stations. * 3 pallets, 630 x 630 mm. * 3-jaw chuck, Ø 650 mm. * Face plate, Ø 900 mm. * Chip conveyor. * Band filter coolant equipment. * Completely covered working area, including safety fence for the pallet changing area. * Separate switch cabinet. * Operating manual. * Approx. 20 tool holders. * Various other accessories. High performance universal turning and milling centre for full range of machining (turning, boring, drilling, milling, and threading) with high speeds and high turning volume. Condition : Good to very good. Machine can soon be inspected under power. Delivery : Ex stock as inspected Payment : Net, after conclusion of contract Thank you for your interest. We have a selection of modern lathes available. Please let us know your requirements

Facing Lathe

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-18011 · Facing Lathe

RAVENSBURG - K 900 KH - - 1966 -

Technical details

Height of centres 550 mm Max. turning Æ 1200 mm Max. turning Æ over slides, approx. 900 mm Max. turning length, approx. 1000 mm Spindle bore, approx. 90 mm 24 spindle speeds 4.3 - 587 rpm Feeds, infinitely variable 1 - 170 mm/min Total load, approx. 25 kW - 380 V - 50 Hz Weight, approx. 8000 kg Accessories/specialities Two separate slides, each equipped with 2-coordinate copying equipment, program controlled by plugboard, strengthened bearings and spindle, hardened and ground guideways, FORKHARDT 3-jaw chuck/ face plate, separate switch cabinet and cooling equipment. This machine is suitable for complicated, high precision copying of heavy workpieces.

Lathe - cycle-controlled

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-791318 · Lathe - cycle-controlled

GILDEMEISTER - NEF 520 - - 1999 -

Technical details

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-695990 · Lathe - cycle-controlled

SOMAB - UNIMAB 400 - - 1996 - NUM Type 1062 T

Technical details

Turning Automatic Lathe - swiss lathe

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-353545 · Turning Automatic Lathe - swiss lathe

TORNOS - ENC 264 - - 1995 -

Technical details

CNC-Sliding Headstock Lathe, Opposite Headstock

Perfil del comerciante: Hans - Jürgen Geiger

Maschinen-Vertrieb GmbH

Contactar con el comerciante

Maschinen-Vertrieb GmbH

James Watt Str. 12

72555 - Metzingen

Alemania

(0049)-7123-18040">(0049)-7123-18040

(0049)-7123-18384

geiger@geiger-germany.com

www.geiger-germany.com

Perfil del comerciante

SERVICIOS

Compramos máquinas y plantas de producción de todo el mundo. Si nos vende sus máquinas, puede estar seguro de una pronta inspección, pago, transporte, etc.

SERVICIO POSTVENTA

Nuestra administración se esfuerza por brindar a cada cliente una consulta experta antes de la venta; y un servicio postventa confiable, también con respecto a la adquisición de piezas de repuesto, etc. Los clientes pueden visitar nuestros almacenes en cualquier momento. Las máquinas que son de interés pueden ser inspeccionadas bajo el poder, después de la cita previa.

TRANSPORTE

Podemos organizar el transporte a un precio razonable si es necesario. Todas las máquinas están protegidas contra la oxidación y se embalan adecuadamente antes de abandonar nuestro stock. Las máquinas que se envían a destinos en el extranjero generalmente se envían en contenedores, y en esta importante área tenemos mucha experiencia en el empaque, por lo que es seguro que las máquinas lleguen en buen estado.

ACCESORIOS Y PIEZAS DE RECAMBIO

Nuestro servicio postventa incluye ayudarlo a adquirir accesorios y piezas de repuesto para nuestras máquinas en el futuro.

Reacondicionamiento y modernización

También podemos recomendar empresas que se especialicen en reacondicionamiento y reacondicionamiento, etc.

ESTIMACIONES DE PRECIO

Si está vendiendo su empresa o sus máquinas de producción, y necesita un presupuesto, nuestro Director, Hans-Jürgen Geiger, es una autoridad calificada (FDM y EAMTM) y estará encantado de ayudarle.

| USTED ESTÁ MUY BIENVENIDO A VISITARNOS | |

Cómo encontrar nuestra empresa si está conduciendo: En el A81 / A8 (en dirección a Múnich), tome la salida a B27 en dirección a Tuebingen / Reutlingen. Después de aproximadamente 10 km, tome la rama de la dirección Metzingen y después de otro 10, tome la 1. Salga de Metzingen (área industrial Laengenfeld), gire a la izquierda en la primera oportunidad y gire a la izquierda en el cruce, después de 150 m nos encuentra en El lado derecho en el James-Watt-street 12. | |

| |

DESCARGAR PDF | |

Esquema de indicaciones en formato PDF. Con el software gratuito Adobe Acrobat Reader, puede ver e imprimir archivos PDF. | |

Nuestra empresa está ubicada cerca del Aeropuerto Internacional de Stuttgart. Estaremos encantados de recogerlo desde allí. Hay una estación de tren en Metzingen. Un horario de trenes está disponible en internet en En www.bahn.. Podemos recogerlo en la estación. Nuestra oficina y salas de exposición están abiertas de lunes a viernes, de 0800 a 1800. Otras veces solo con cita previa. Estamos cerrados por dos semanas por las vacaciones de Navidad, desde 21st diciembre hasta 7th January. Metzingen se encuentra en una zona muy bonita en el sur de Alemania. Es famoso por sus buenos vinos y por sus diversos establecimientos de fábrica (incluidos Hugo Boss y Escada). Podemos ayudarlo a encontrar un buen hotel si desea pasar algún tiempo aquí. | |

Lathes have stood the test of time as some of the most efficient and multi-functional tools. They can be used on a wide variety of material surfaces and can serve a huge number of functions. Whether you need a small lathe for home use or an industrial size lathe for large-scale production, you can find the perfect piece of used equipment to suit your needs at LagerMaschinen. Visit this easy-to-use forum to find the best used machinery for your needs.

LagerMaschinen - your home for used machinesLathes are critical pieces of equipment in a wide variety of sectors. A lathe is capable of grinding, cutting and finishing tiny parts for watch- and jewellery-making, as well as large-scale pieces for automobiles and airplanes. Whether you prefer the control offered by a manually operated lathe or the precision and efficiency of a computer numerical controlled (CNC) lathe, you can find a huge selection at LagerMaschinen, your best source for used machinery.

Buying used machines is a smart investmentSmart shoppers know that you dont have to sacrifice quality for affordability when buying machinery for your home or business. Buying used machines is a great way to get the quality you need without straining your budget. If youre in the market for lathes, saws, grinders or any other equipment, you can find a great selection of used machines at LagerMaschinen. Sort results by price, location or brand and find the best used machines around.

TOP Manufacturer:

ZMM - KRAFT - GILDEMEISTER - INDEX - WEILER - MORI SEIKI - HUVEMA - COLCHESTER - MAZAK - BERNARDO -

James-Watt-Str. 12

Contact Trader

James-Watt-Str. 12

72555 - Metzingen

Deutschland

(0049)-7123-18040

(0049)-7123-18384

geiger@geiger-germany.com

www.geiger-germany.com

Contact person: