Machine data

Document

No hay más documentos disponiblesTechnical details

| max. wheel diameter | 400 mm |

| max. number of teeth | 150 |

| max. module | 5 |

| total power requirement | 16 kW |

| weight of the machine ca. | 10 t |

Videos

No hay archivos de video disponiblesAdditional information

Workpiece Ø, min./max. 30 - 400 mm

Number of teeth 6 - 150

Module range, max. 5

Tool holder shaft Ø SK 30 / 20

Tool speeds 4,000 rpm

Spindle drive max. infinitely variable 1.8 kW

Feeds, longitudinal and cross 0.001 - 12 m/min

Workpiece speed, max. (1.5 kW) C Axis 2,000 rpm

Workspindle slide 400 mm

Tool speed, max. 3,000 rpm

Tool holder SK 30

Total electrical load, approx. 16 kW - 380 V - 50 Hz

Weight, approx. 10,000 kg

Accessories / Special Features

* BWO (HECKLER & KOCH) CNC Control model 785 H for altogether 7 axes. Input via monitor. The control has all the supervision and fault diagnosis features necessary for fully automatic working process.

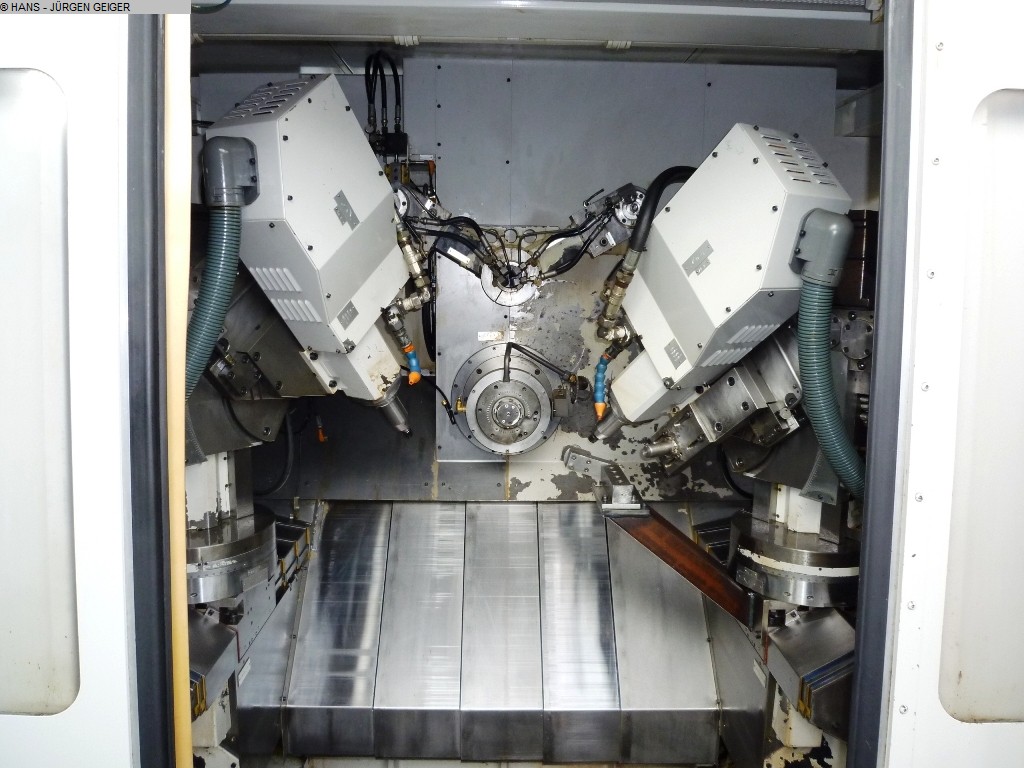

* 2 workspindle units, left and right, which can be set at any angle.

* CNC controlled: Z and W Axes for tool cross slide. X and U Axes for tool longitudinal slide.

* L and O Axes for milling spindle. C Axis for workspindle rotation.

* Manually controlled: Tool slide rotary table (B and E Axes). Tool slide vertical infeed (V and Y Axes). Tilt of tool head (A and D Axes). All axes have digital display in the control.

* Hydraulically operated workpiece clamping device in conjunction with an automatic loading device using workpiece feed / conveyor belt and swivelling loading device, as well workpiece control by air.

* Coolant equipment with chip conveyor.

* Noise protection cabin. * Central lubrication.

* Built-on hydraulic unit. * Pneumatically driven safety doors. * Deburring device, etc.

The machine uses the hypocycloidal milling principal, with electronically synchronized tool and workpiece axes for working straight roof-formed teeth, symmetric as well as asymmetric forms. Advantages are high precision and productivity.

Condition : Good to very good. Machine can soon be inspected under power.

Delivery : Ex stock, as inspected

Payment : Net, after conclusion of contract

Thank you for your interest. We always have a good selection of gear machines available on stock.

Number of teeth 6 - 150

Module range, max. 5

Tool holder shaft Ø SK 30 / 20

Tool speeds 4,000 rpm

Spindle drive max. infinitely variable 1.8 kW

Feeds, longitudinal and cross 0.001 - 12 m/min

Workpiece speed, max. (1.5 kW) C Axis 2,000 rpm

Workspindle slide 400 mm

Tool speed, max. 3,000 rpm

Tool holder SK 30

Total electrical load, approx. 16 kW - 380 V - 50 Hz

Weight, approx. 10,000 kg

Accessories / Special Features

* BWO (HECKLER & KOCH) CNC Control model 785 H for altogether 7 axes. Input via monitor. The control has all the supervision and fault diagnosis features necessary for fully automatic working process.

* 2 workspindle units, left and right, which can be set at any angle.

* CNC controlled: Z and W Axes for tool cross slide. X and U Axes for tool longitudinal slide.

* L and O Axes for milling spindle. C Axis for workspindle rotation.

* Manually controlled: Tool slide rotary table (B and E Axes). Tool slide vertical infeed (V and Y Axes). Tilt of tool head (A and D Axes). All axes have digital display in the control.

* Hydraulically operated workpiece clamping device in conjunction with an automatic loading device using workpiece feed / conveyor belt and swivelling loading device, as well workpiece control by air.

* Coolant equipment with chip conveyor.

* Noise protection cabin. * Central lubrication.

* Built-on hydraulic unit. * Pneumatically driven safety doors. * Deburring device, etc.

The machine uses the hypocycloidal milling principal, with electronically synchronized tool and workpiece axes for working straight roof-formed teeth, symmetric as well as asymmetric forms. Advantages are high precision and productivity.

Condition : Good to very good. Machine can soon be inspected under power.

Delivery : Ex stock, as inspected

Payment : Net, after conclusion of contract

Thank you for your interest. We always have a good selection of gear machines available on stock.

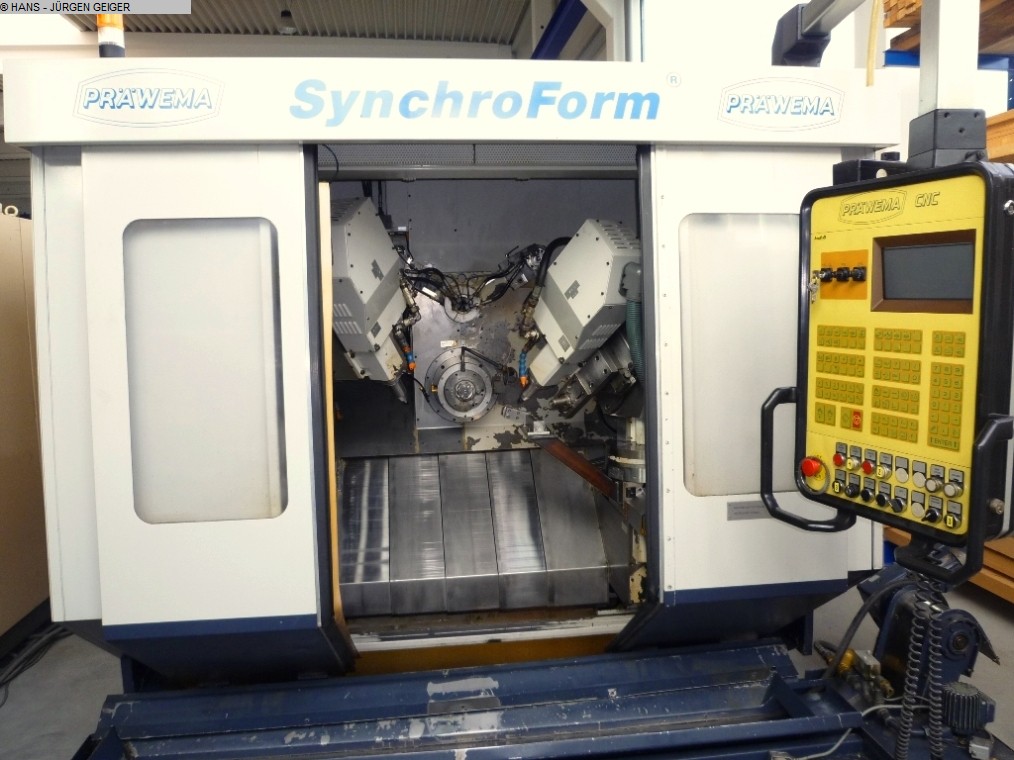

On this page you will find a an offer on a used Chamfering and Deburring Machine of type W 2 - 1 SYNCHROFORM of the company PRÄWEMA with year of construction 1991 and with stock no.: 1049-347971. The machine is manufactured by the company HANS - JÜRGEN GEIGER Maschinen-Vertrieb GmbH from 72555 Metzingen offered. The delivery time / delivery status for this machine is: immediately For more information, please refer to the details listed.

Documentos y videos

No hay más documentos disponibles

No hay archivos de video disponibles

Machine

Chamfering and Deburring Machine